Dispersion strengthening

What is dispersion strengthening?

Dispersion strengthening is a process carried out to improve the properties of metals by adding additional metallic material to create an alloy.

The addition of an alloying metal to a base metal can increase the strength, resistivity to corrosion and enable materials to operate at higher temperatures.

This new material is referred to as second phase when the alloying metal is added in an amount sufficient to allow the base material to reach its solubility limit, so any additional alloying metal becomes insoluble.

A heterogenous microstructure is then created consisting of two or more different types of crystals of the different phases, combined in different quantities

How is it done?

The insoluble, second phase particles are introduced to the base metal.

In high strength engineering materials, second phase materials are the most potent strengthening agent. Common examples include are added to Iron-base, aluminium, nickel, titanium alloys.

The mechanical properties of an alloy are determined by the size, shape and number of second phase particles added

The effect of adding second phase particles dispersed throughout the matrix is to block dislocation motion, which then strengthens the material. In order for plastic deformation to occur, a much greater stress is now needed.

Orowan Mechanism

The disruption caused by dislocation can be seen in the Orowan (or dislocation bowing) mechanism diagram below.

- As a dislocation line approaches particles, a dislocation loop is formed around these particles, this process is called bowing.

- The dislocation loop formed then interacts with future dislocation lines.

- The movement of the dislocation is slowed down

- This slowing down increases the strength of the material.

The particle size and volume of alloying particles are key factors for determining the increased strength,

- Larger particles: the strengthening effect decreases

- Small particles: the strengthening effect increases

- Higher the volume of particles increases the strength as they will be tightly packed.

Oxide dispersion strengthened alloys (ODS alloys)

Adding other metals to a base metal is not the only way to change its properties. In this section we will focus on the addition of Oxides.

Oxide dispersion alloys are used where extreme operating conditions are expected, as they are highly resistant to creep and maintain good strength at high temperatures.

Applications include; high temperature turbine blades (thermal power stations), heat exchanger tubing, aerospace and within the nuclear industry.

The properties of ODS alloys greatly depend on the microstructure, such as the grain size of the alloy matrix, the morphology, size and distribution of the oxide second phase particles.

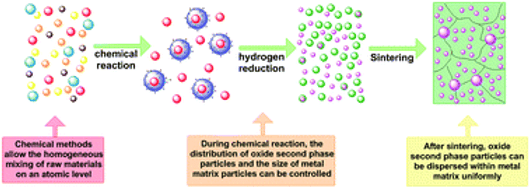

Most ODS alloys are prepared by sintering as shown below.

The primary factor for determining the microstructure and properties is determined by the composite powder precursor.

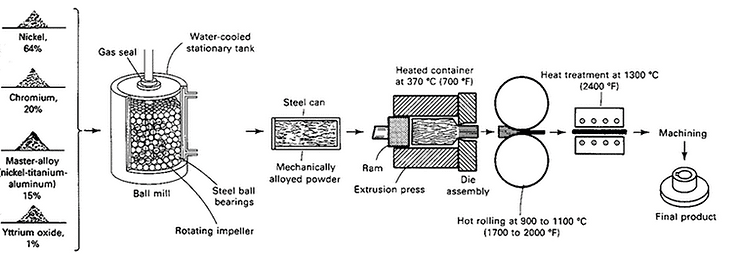

Oxide dispersion strengthened (ODS) alloys are produced by the mechanical alloying of powders.

Figure 1 – ODS alloying process

The powder constituents can be in the elemental, intermetallic or pre-alloyed state.

- The metal and oxide powders are blended and mechanically alloyed using a ball mill, which is a grinder filled with steel balls placed in a rubber container, as the container rotates, the balls drop and impact with the powder, this reduces particle size.

- The powders become smeared together due to the repeated impacts.

- Shearing generates a fine mixture of the constituents.

- This powder is then packed into sealed containers, which are hot worked into simple shapes.

- The resultant product is dense and fine grained (less than 11µm) but has highly developed, directional residual strain.

- The alloys are then re-crystallised at about 1280-1350°C which forms large and highly elongated grains.

Case study

The effect of Al2O3 dispersion on the mechanical properties of Titanium Aluminide (TiAl).

The following section will compare the mechanical properties of a pure alloy of Titanium Aluminide with the alloy strengthened with Al2O3 dispersion.

The combination of mechanical properties for this alloy, at high temperatures, are superior to those of other superalloys.

Because of their high temperature specific strength and elastic modulus, low density along with good resistance against oxidation and corrosion, applications include low pressure gas turbine engines and various automotive applications

In this investigation 3% volume of Al2O3 is added to the alloy and test specimens were produced consisting of the TiAl alloy and the dispersion strengthened alloy, both samples have the same geometries.

Flexural bending testing was carried out across a high range of temperatures.

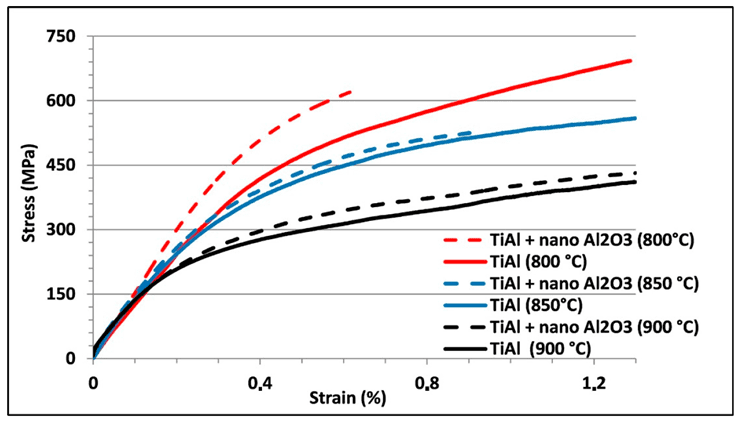

Stress strain curves were generated from the experimental data.

Figure 2 – Stress vs. strain curve from bending tests at various temperatures

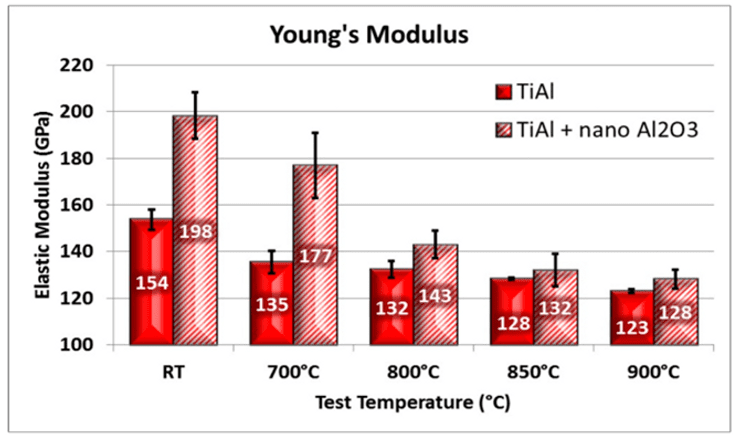

Figure 3 – Young’s modulus from bending tests at various temperature

Analysis

- As the temperature increases there is a general reduction in tensile strength.

- The young’s modulus decreases as temperature increases.

The trends are the same for both sample materials.

The dispersion strengthened alloy has a higher tensile strength at all operating temperatures.

The Young’s modulus is also higher at every temperature and corresponds to a maximum of a 30% increase at room temperature. The effect on Young’s modulus becomes significantly less at higher temperatures.

Conclusion

The results show dispersion strengthening is particularly effective in increasing strength at high temperatures, where other strengthening mechanisms lose their effectiveness.

Online Engineering Courses and Diplomas

To learn more about this topic or others in engineering, enrol on to one of our accredited online engineering courses today.

Why not check out the online engineering short courses specifically in manufacturing engineering:

Recent Posts

How can we analyse a single-degree-of-freedom lumped parameter systems with damping?

How can we analyse a single-degree-of-freedom lumped parameter system with damping? In our previous article on undamped vibration, we looked at solving vibration problems with a single degree of freedom. In this article, we’re going to look at systems with damping and how to analyse them. We’ll focus on the mathematical analysis of a single-degree-of-freedom […]

How can we analyse undamped vibration problems.

How can we analyse undamped vibration problems. In our previous article on harmonic motion, we looked at how we can analyse problems involving simple harmonic motion, now we’re going to look at solving vibration problems with a single degree of freedom. Vibration Analysis In vibration analysis, there are two approaches we are interested in. One […]

How do we analyse problems involving harmonic motion?

How do we analyse problems involving harmonic motion? In our previous article on mechanical resonance, we looked at harmonic motion and how it affects structures. Now we’re going to jump into how we can solve issues that involve simple harmonic motion. What is simple harmonic motion? Many systems consist of components that vibrate in the […]