Introduction to the Capacitor in Electrical Engineering

We can think of capacitors are short term ‘charge-stores’. In other words, capacitors just store charge inside them. A capacitor consists of two metal plates separated by a layer of insulating material called a dielectric.

There are 2 types of capacitor:

- Electrolytic capacitors. These hold much more charge and must be connected with the correct polarity, otherwise they can explode.

- Non-electrolytic. These hold less charge and can be connected either way round in a circuit.

How Does a Capacitor Work?

When two conducting plates are connected to a battery, electrons move towards one plate. The positive plate loses electrons , eventually leaving both plates with equal and opposite charge, +Q and -Q. When a capacitor is charged, we say that the capacitor has charge Q.

Define Capacitance

Capacitance, C = “the charge, Q, required to cause potential difference, V, in a conductor. It is measured in Farads”.

“1 Farad is the capacitance of a conductor, which has potential difference of 1 volt when it carries a charge of 1 coulomb”.

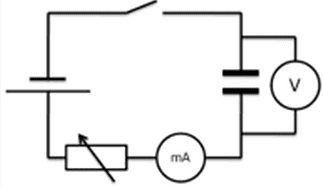

Charging a Capacitor Using D.C.

At any time, t, after the switch is closed, the charge, Q, on the capacitor can be calculated using Q=It where I = the current (Amps).

The variable resistor can be altered to keep the current constant.

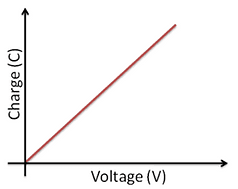

Plot a graph of capacitance against voltage and since:

The gradient of the graph will equal the capacitance of that capacitor.

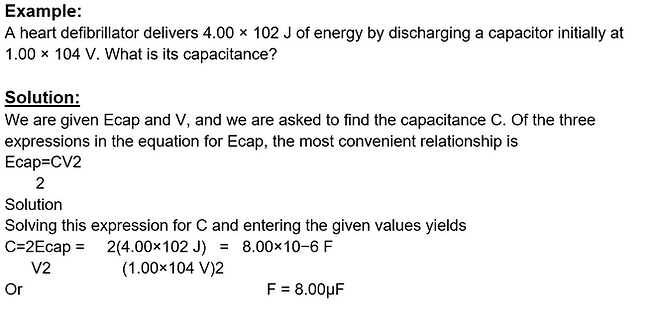

Charge Stored in a Capacitor

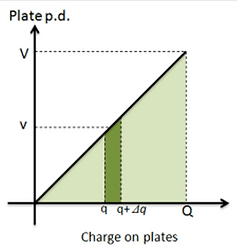

Electrical potential energy is stored when a capacitor is charged.

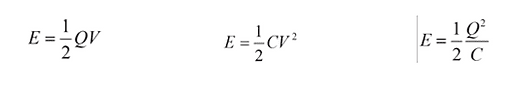

The area under this graph is equal to the energy stored = (½bh)

We can combine previous equations to give the following:

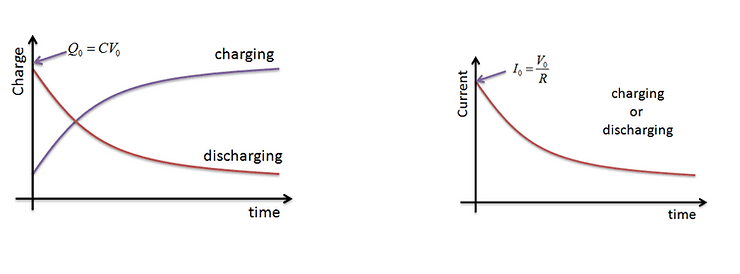

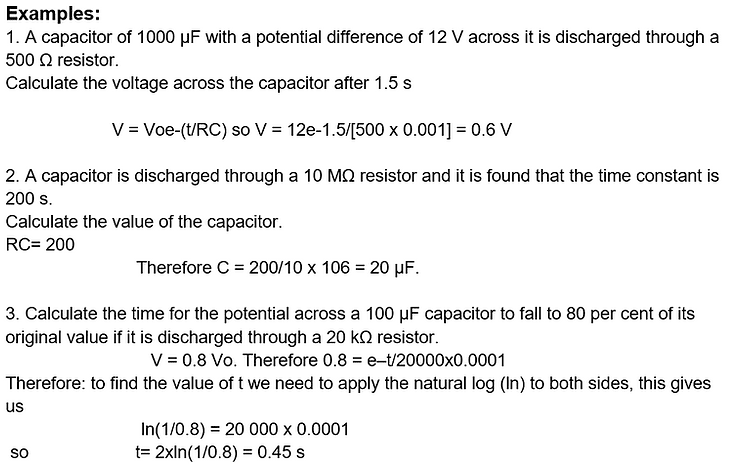

Charging and Discharging a Capacitor

When discharging, the current decreases with the potential difference, p.d. This decrease is exponential as can be seen below. Q0, V0 and I0 are all the initial charge, voltage and current through the capacitor at the initial discharge.

Decay Curve

Let us now examine the process of discharging the capacitor. Charge, Q, falls to 1/e of its initial value in a time equal to the time constant, RC.

When the initial charge is Q0,

- After RC seconds = 0.37 x Q0

- After 2RC seconds = 0.37 x 2 x Q0

- After nRC seconds = 0.37n x Q0.

The time taken to halve, T½, is always the same:

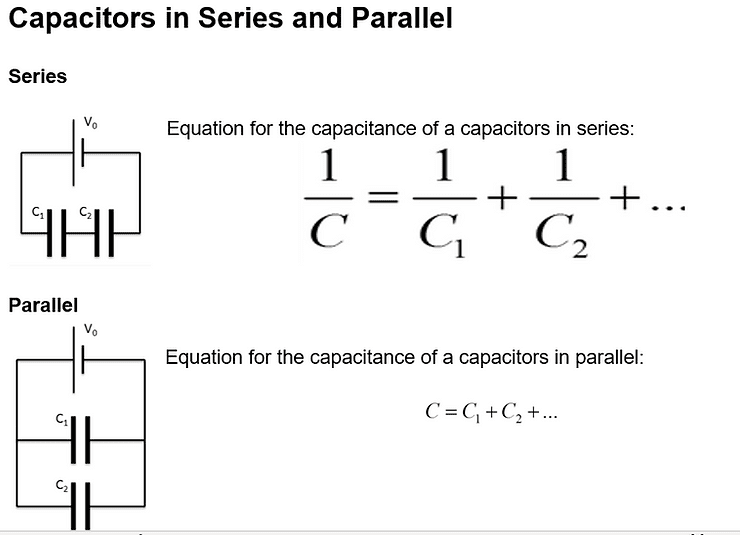

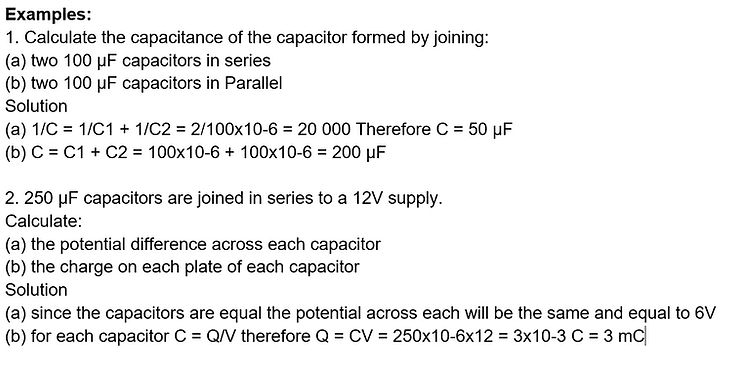

Example of Capacitors in Series and Parallel

Interested in electrical and electronic engineering? Find out more about all the electrical engineering courses we have available by clicking here.

Diploma in Electrical Technology

Diploma in Renewable Energy (Electrical)

Diploma in Electrical and Electronic Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]