The Basics of Operating Envelopes and Operational Modes in Automation

Introduction

In industrial settings, the work envelope of a robot is crucial for evaluating its functionality. Articulated arm robots have a significant advantage in this regard, as they can utilise nearly all of their work envelope, making them highly effective for a variety of tasks.

Work Envelope of an Articulated Robot

Work Envelope: This is the three-dimensional space within which a robot can operate and perform tasks. It defines the maximum reach of the robot’s arms in all directions and varies based on the robot’s type. A larger work envelope allows the robot to interact with more areas around it, increasing its versatility and productivity.

Footprint: The footprint refers to the amount of physical space the robot occupies on the floor. It’s essentially the area taken up by the robot’s base, including any supporting structures or attachments. A smaller footprint means the robot occupies less space on the factory floor, leaving more room for other equipment or activities.

In industrial robotics, maximising the work envelope relative to the footprint is ideal. This allows robots to reach a broader area without consuming excessive floor space, making articulated robots particularly valuable since they generally have extensive reach for a compact base. This ratio is essential in environments where space efficiency, safety, and production flow are top priorities.

One key benefit of articulated robots is that, irrespective of how cables are managed, even basic models can maximise the usable workspace relative to their footprint on the factory floor. This maximised reach and flexibility make them particularly valuable in environments where production flow, safety, and efficient floor space use are essential. By occupying minimal floor space while providing extensive reach, these robots allow factories to streamline operations, maintain safety zones, and optimise available space, all of which are critical factors in high-efficiency production settings.

Typical work envelopes for each type of robot.

Cartesian Configuration

A Cartesian robot’s work envelope, shaped like a rectangular prism, allows it to access every point within its range without any dead zones. This uniform reach means the robot can move freely and consistently across its entire working volume. Additionally, the Cartesian configuration enables the robot to handle its maximum payload capacity throughout this space, providing stable, reliable support for heavy items. Its linear movements along the X, Y, and Z axes ensure high precision and stability, making it ideal for applications requiring exact positioning, such as assembly, CNC machining, and material handling where tasks demand both precision and full-area coverage within a defined workspace.

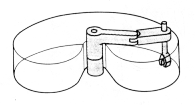

Cylindrical Configuration

A cylindrical robot’s work envelope is a cylindrical shape with a hollow centre, creating a cylindrical dead zone around its base. This dead zone exists because the arm cannot retract fully to the centre of the robot. Despite this limitation, the cylindrical configuration is effective for tasks requiring broad radial and vertical reach, such as assembly, material handling, and machine loading, where items are positioned around the robot’s perimeter.

Polar Configuration

This robot configuration has a work envelope between two partial spheres, with conical dead zones above and below due to restricted angular movement. Although it can’t reach vertically this setup provides effective motion within its accessible range, making it suitable for tasks not requiring full vertical reach.

SCARA Configuration

The SCARA (Selective Compliance Assembly Robot Arm) configuration has a heart- or kidney-shaped work envelope with a circular hole in the centre. This design provides broad coverage in the horizontal plane but limited reach in the vertical plane. This configuration is ideal for tasks that require extensive lateral movement, such as assembly and material handling, where vertical reach is less critical.

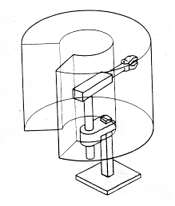

Revolute Configuration

This robot configuration is efficient in terms of floor space, offering a large work envelope relative to its footprint.

The shape of this envelope varies by design:

Design (1): Allows the robot to reach nearly a spherical work envelope, providing extensive reach in all directions.

Design (2): Has a more complex, cusp-shaped envelope, which may have areas of restricted reach.

These designs allow flexibility in applications, with the spherical design offering a more universally accessible work volume, while the cusp shape may be tailored for specific tasks within a defined range.

Operational Modes

Robots in industrial and commercial settings operate in different modes, each tailored to specific tasks, safety needs, and operational efficiency. Manual mode allows operators to control the robot directly for setup and maintenance, while automatic mode enables the robot to perform pre-programmed tasks autonomously, ideal for high-speed, repetitive production. In teach mode, operators guide the robot to record complex movements, making it versatile for task adjustments. Collaborative mode allows robots to work safely alongside humans with built-in safety features, and simulation mode enables virtual testing to optimise tasks before real-world application. Together, these modes allow robots to adapt to diverse tasks, enhancing productivity and safety in various work environments.

Teach Mode

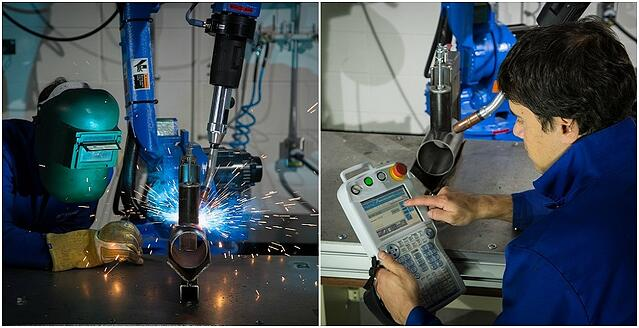

A teaching pendant is a handheld device used to control and program industrial robots, enabling operators to guide and teach the robot specific movements and tasks. Teaching pendants are essential for setting up, configuring, and modifying robot functions, making them highly valuable in industrial and manufacturing settings.

Key features of teaching pendants include:

Manual Control: They allow operators to manually control each of the robot’s joints and movements, positioning the robot precisely in space.

Recording Movements: Teaching pendants enable users to “teach” the robot by recording sequences of movements, which the robot can then repeat autonomously in automatic mode.

Graphical Interface: Many teaching pendants come with a graphical interface, often a touchscreen, which provides visual feedback and easy access to programming functions, simplifying complex tasks.

Safety Features: Most teaching pendants have emergency stop buttons and dead-man switches to ensure safe operation, especially when the robot is operating at close range to humans.

Programming Functions: In addition to movement control, teaching pendants allow users to set parameters, speed, and operational logic, giving full control over how tasks are executed.

Teaching pendants make it easy to adjust robotic tasks without extensive reprogramming, making them a critical tool for operators to fine-tune robotic operations, adapt to new tasks, and ensure high precision in complex environments.

Teach Pendant offers both advantages and disadvantages in controlling and programming industrial robots.

Advantages

- Precision and Control: Teach pendants allow operators to control each robot joint and movement manually, enabling precise positioning for complex tasks.

- Ease of Programming: Operators guide the robot through a task sequence, teach pendants simplify programming, especially for users without extensive coding experience.

- Flexibility: Operators can easily adjust or reprogram tasks, making them ideal for environments where robots need to handle different tasks or products.

- On-the-Spot Training: Teach pendants provide real-time, hands-on training, making them a great tool for learning and experimenting with robot functionality without needing pre-written code.

- Enhanced Safety: Most pendants come with emergency stop buttons and safety switches, ensuring operator safety during programming and testing phases.

Disadvantages

- Learning Curve: Operating teach pendants can require training, especially for complex or high-tech models, which may slow down productivity in the beginning.

- Time-Consuming for Complex Paths: Programming complex or lengthy tasks by manually guiding the robot can be time-consuming and may be less efficient than using offline programming tools.

- Limited Range of Control: Some basic teach pendants may lack advanced features, limiting their ability to program intricate operations, such as conditional logic or multiple axes simultaneously.

- Risk of Human Error: Manual programming with a teach pendant can lead to errors if not carefully managed, potentially affecting the robot’s performance or safety.

- Dependence on Physical Proximity: The operator must be near the robot to use the teach pendant, which could be limiting in large, complex environments where remote programming would be advantageous.

Simulation/Offline Programming

Offline programming, or simulation, is widely used in robotics to test control algorithms in research and optimise programming in industrial settings without interrupting production. In industry, it is especially beneficial for small and medium enterprises (SMEs), where robots often need frequent reconfiguration for different tasks. By programming offline, companies can reduce downtime, allowing production to continue while new programs are developed and tested virtually. This method uses a virtual mockup of the robot and task, providing a safe and efficient way to test ideas and detect potential issues before implementation on the actual robot.

Modern simulation software packages have also become more intuitive and user-friendly, making it easier for operators and engineers to experiment with different setups and quickly validate ideas before applying them on the factory floor. This can lead to significant productivity gains, streamlined processes, and minimise errors.

Offline programming for robots has several advantages and disadvantages, impacting how it’s used in both research and industry settings.

Advantages

- Minimises Production Downtime: Programming tasks are done virtually, meaning robots remain operational on the production floor while new programs are created and tested.

- Improves Efficiency: Tasks can be tested, adjusted, and optimised in a virtual environment, allowing for quicker implementation and reducing time spent troubleshooting.

- Enhances Safety: Simulation in a virtual space eliminates the risk of errors causing accidents or equipment damage during initial testing, which is especially valuable when working with heavy machinery.

- Flexibility for Reconfiguration: Offline programming is ideal for environments where robots frequently change tasks, such as in SMEs, enabling rapid adjustments without disrupting production.

- Cost Savings: Less downtime and reduced risk of equipment wear or damage during testing mean potential cost savings over time.

- Error Detection and Optimization: Simulating movements and interactions allows for early detection of issues, enabling adjustments before implementation and optimising performance for complex tasks.

Disadvantages

- Initial Setup Costs: Offline programming software can be expensive, requiring an upfront investment in software and, in some cases, high-performance hardware.

- Learning Curve: There may be a significant learning curve associated with mastering the simulation software, which can require specialised training for operators and engineers.

- Potential Discrepancies with Real-World Conditions: Simulations may not perfectly replicate real-world conditions, such as minor variances in physical properties or unexpected environmental factors, potentially leading to adjustments after deployment.

- Dependency on Accurate Models: The effectiveness of offline programming depends on the accuracy of the virtual model. Inaccurate mockups can result in flawed programming that may require rework once tested on the physical robot.

- Limited Real-Time Feedback: Unlike direct programming or teach pendants, offline programming lacks immediate physical feedback, making it challenging to identify subtle movement issues until the program is transferred to the actual robot.

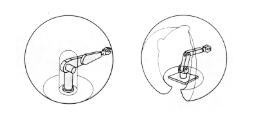

Teaching by Demonstration

Teaching by demonstration is a hands-on programming method that adds an intuitive alternative to the traditional teach pendant, allowing operators to guide the robot through movements directly. This approach involves physically moving the robot arm, either by manipulating a force sensor or using a joystick attached to the robot’s wrist, just above the end effector. The operator then stores each position in the robot’s memory, creating a program that the robot can replicate.

Many collaborative robots (cobots) have integrated this method, making it accessible for operators to begin using the robot with minimal training. Since it allows immediate interaction, teaching by demonstration is particularly valuable in environments where robots frequently change tasks, as it provides a fast, flexible programming option without requiring extensive technical knowledge. This approach can streamline programming for applications where precision and quick setup are needed, making it ideal for small and medium enterprises and versatile production lines.

Advantages

- Ease of Use: Teaching by demonstration is highly intuitive, allowing operators to program robots with minimal training. Operators can simply move the robot arm to desired positions, making it accessible for those without extensive robotics experience.

- Quick Setup and Flexibility: This method is ideal for tasks that require frequent reconfiguration, as it enables fast, on-the-spot programming. It’s particularly valuable for small and medium enterprises (SMEs) or dynamic production environments.

- Reduced Programming Time: Compared to traditional programming methods, teaching by demonstration often requires less time to set up, making it ideal for short production runs or custom tasks.

- Improved Precision for Complex Movements: Operators can manually adjust the robot’s movements in real-time, allowing for precise and efficient programming of complex or delicate tasks that may be challenging to code.

- Enhanced Safety: Many collaborative robots use force sensors or joysticks, allowing operators to program them safely by hand, despite close human-robot interaction.

Disadvantages

- Limited Complex Programming Capability: Teaching by demonstration is less effective for tasks requiring advanced programming logic, such as conditional statements, loops, or sensor integration, which may require additional coding.

- Accuracy Limitations: The precision achieved with manual manipulation may not match that of programming directly through numerical input or CAD-based offline programming, especially for tasks requiring high accuracy or repeatability.

- Physical Fatigue and Ergonomics: Manually guiding the robot through multiple complex motions can be physically tiring and may pose ergonomic challenges, particularly for larger robots.

- Potential for Human Error: Programming through physical demonstration can lead to small inaccuracies or inconsistencies, especially if the same task needs to be reproduced with exact precision.

- Dependence on the Robot’s Force Sensors and Joystick Quality: The quality and responsiveness of the force sensors or joystick directly impact the ease and accuracy of programming. Low-quality sensors can make programming cumbersome and less precise.

Auto Mode

After programming a robot in Teach Mode, the robot controller can be switched to Auto Mode to execute the saved program. In Auto Mode, the robot performs the programmed tasks autonomously, following the exact movements and sequences recorded during the teaching process. This is the primary mode used in production, where the robot carries out repetitive tasks with speed, precision, and consistency.

Auto Mode allows the robot to operate independently, increasing efficiency by performing tasks without further manual input, essential for high-volume production environments, where continuous, reliable performance is necessary to maintain workflow and productivity.

Interested in our Electrical Engineering Courses?

At iLearn Engineering®, we offer a diverse range of online accredited electrical engineering courses and qualifications to cater to different academic and career goals. Our courses are available in varying credit values and levels, ranging from 40 credit Engineering Diplomas to a 360 credit International Graduate Diploma.

Short Courses (40 Credits)

A selection of our more popular 40 credit electrical diplomas…

Diploma in Electrical and Electronic Engineering

Diploma in Electrical Technology

Diploma in Renewable Energy (Electrical)

First Year of Undergraduate (Level 4 – 120 Credits)

Higher International Certificate in Electrical and Electronic Engineering

First Two Years of Undergraduate (Level 5 – 240 Credits)

Higher International Diploma in Electrical and Electronic Engineering.

Degree equivalent Graduate Diploma (Level 6 – 360 Credits)

International Graduate Diploma in Electrical and Electronic Engineering

All Electrical and Electronic Courses

You can read more about our selection of accredited online Electrical and Electronic Engineering courses here.

Complete Engineering Course Catalogue (all courses)

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]