Electromagnetic Transducers, Actuators and Sensors: Principles, Design, and Real-World Applications

Introduction

Electromagnetic transducers and actuators are at the heart of countless modern technologies, quietly enabling everything from smartphones and medical devices to industrial automation and transportation systems. A transducer converts one form of energy into another, often transforming electrical signals into mechanical motion or vice versa, while an actuator uses that energy to drive movement or perform a task. Built on the fundamental principles of electromagnetism, these devices combine precision with reliability, making them essential in bridging the gap between electronic control systems and the physical world.

In this article, we’ll explore the underlying principles that govern their operation, examine their construction and design, and highlight the many real-world applications where they play a vital role. Whether it’s a loudspeaker producing sound, a sensor measuring position, or a motor powering automation, electromagnetic transducers and actuators are the unseen forces that bring technology to life.

What is a Transducer?

An electrical transducer is a crucial component in instrumentation, allowing for the conversion of various physical quantities, such as temperature, pressure, displacement, or level into corresponding electrical signals like voltage or current. This electrical output is directly proportional to the physical quantity being measured, enabling accurate monitoring and control of physical systems.

For instance, consider a temperature transducer. When exposed to heat, it converts the temperature into a proportional electrical potential, often voltage. This signal can then be fed into a control system, which may display the temperature reading, trigger an alarm if the temperature exceeds a set threshold, or even adjust a related system to maintain optimal conditions.

Instrumentation, the science of measurement and control, heavily relies on transducers. In this field, transducers serve as foundational devices that convert physical parameters, such as flow, angle, or level into measurable and controllable quantities, allowing for precise monitoring and automation.

While all transducers convert one form of energy into another, electrical transducers specifically convert physical quantities into electrical signals. This distinction is crucial as it allows seamless integration with electronic control and measurement systems. For example, while a loudspeaker is also a transducer (converting electrical signals into sound), it is not an electrical transducer because it doesn’t convert a physical quantity to an electrical one.

Types of Transducer

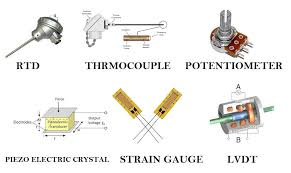

There are of many different types of transducer, some of the classification methods are:

Types of Transducer based on Quantity to be Measured

- Temperature transducers

- Pressure transducers

- Displacement transducers

- Oscillator transducer

- Flow transducer

- Inductive transducer

Types of Transducer based on the Principle of Operation

- Photoconductors

- Photovoltaic

- Piezoelectric transducer

- Chemical

- Mutual induction

- Electromagnetic

- Hall effect

Types of Transducer based on Power Sources

Active transducers

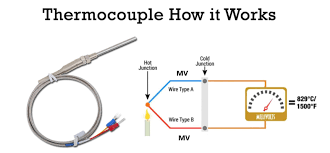

Active Transducers are devices that generate electrical output directly from the physical quantity they measure without needing an external power source. They work on the principle of energy conversion, meaning they convert the energy from the measured physical quantity itself into an electrical signal. A classic example of an active transducer is the thermocouple. When exposed to a temperature difference, a thermocouple generates a voltage that is directly proportional to the temperature it senses. This voltage can then be used to monitor or control temperature without any external power.

Characteristics of Active Transducers: They produce an electrical signal as a direct response to the input, like pressure or temperature. They do not rely on an external power source to function, making them ideal for remote or low-power applications. They convert one form of energy (e.g., thermal, mechanical) directly into electrical energy.

Examples of Active Transducers

- Thermocouple: Converts thermal energy into electrical voltage.

- Piezoelectric Crystal: Generates a voltage in response to mechanical stress, commonly used in pressure and vibration sensors.

- Photovoltaic Cell: Converts light energy into electrical energy, often used in solar power applications.

Active transducers are widely used in applications where simplicity and reliability are essential, especially in situations where supplying power to the transducer might be challenging.

Passive Transducers

Passive Transducers are devices that require an external power source to operate. They do not generate an electrical signal directly from the physical quantity they measure. Instead, they create an output in the form of a variation in a specific electrical parameter, such as resistance, capacitance, or inductance, which must then be converted into an electrical signal (voltage or current) by additional circuitry. For example, a photocell or Light Dependent Resistor (LDR) is a passive transducer that changes its resistance based on the light intensity it receives. When light falls on the LDR, its resistance decreases, and this variation can be detected using a bridge circuit that translates the change in resistance into a proportional electrical signal.

Key Characteristics of Passive Transducers

Passive transducers need an external source to provide the power for their operation. They produce an output by altering an electrical parameter like resistance, capacitance, or inductance. An external circuit, such as a bridge circuit, is necessary to convert the parameter change into a usable electrical signal.

Examples of Passive Transducers

- Photocell (LDR): Changes resistance with light intensity.

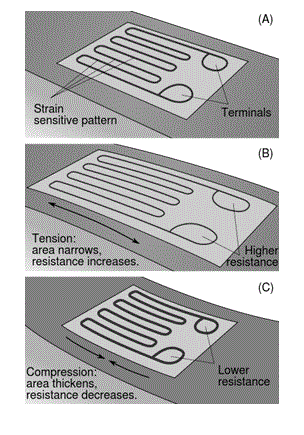

- Bonded Strain Gauge: Changes resistance with applied stress or pressure.

- Capacitive Humidity Sensor: Alters capacitance based on the moisture content in the air.

- Thermistor: Varies resistance in response to temperature changes.

Passive transducers are widely used where the change in physical quantity does not generate its own electrical signal, and a small variation needs to be amplified for effective measurement and control.

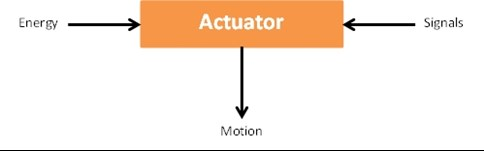

What is an actuator?

An actuator is a device that enables motion by converting energy and signals into physical movement. Actuators are essential components in automation and control systems, transforming energy (such as electrical, pneumatic, or hydraulic) into either linear or rotary motion based on specific requirements.

Types of Actuator Motion

Linear Actuators:These actuators produce movement along a straight path, meaning they can extend or retract in a single plane, common applications include pushing or pulling objects within a fixed range.

Example: In manufacturing, linear actuators can position tools or parts along a production line.

Rotary Actuators: Rotary actuators provide rotational movement, revolving around a circular plane. Unlike linear actuators, they are not confined to a set path and can continuously rotate in one direction as needed.

Example: Rotary actuators are used in conveyor belts or rotating machinery.

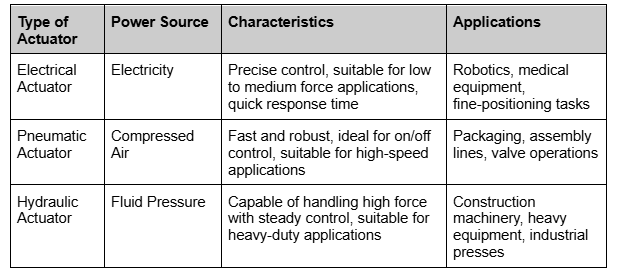

Types of Actuators Based on Power Source

Actuators can vary based on their power supply, with each type having unique characteristics suited to different applications:

Choosing the Right Actuator: The choice between these actuator types depends on the application’s specific requirements, such as force needed, control precision, speed, and environmental conditions. For instance:

Electrical actuators are ideal for applications requiring fine control and positioning, such as robotics or medical equipment.

Pneumatic actuators are well-suited for high-speed, high-cycle applications where quick, repetitive motion is necessary.

Hydraulic actuators are the go-to option for heavy-load applications where significant force and durability are needed, like in construction and manufacturing.

In essence, actuators are crucial for translating control signals into physical actions, making them indispensable in automation, manufacturing, and many other industries.

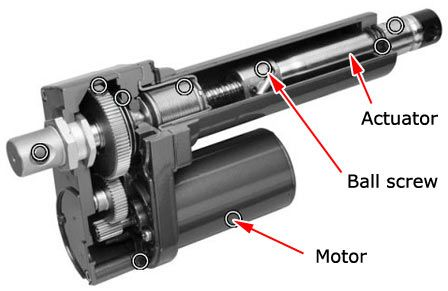

How does an electrical linear actuator work?

Electric linear actuators are commonly designed with a DC motor paired with a transmission, typically a worm gear connected to a screw/nut assembly. This combination effectively converts the rotational motion of the DC motor into a precise linear motion. This design offers several advantages, making electric linear actuators a popular choice in many industries.

The worm gear and screw/nut assembly provide a low-noise solution, making these actuators suitable for applications requiring minimal sound. Electric linear actuators consume less power and provide smooth, controlled motion, ensuring efficient energy use.

With an easy-to-drive design, these actuators can be powered by a simple battery connection, enhancing their safety, especially in mobile applications. The self-lock system ensures that the actuator holds its position even under an external load, preventing it from reversing without intentional control.

Advantages Over Hydraulic and Pneumatic Actuators

Electrical actuators are simpler to install since they don’t require complex systems like valves, pumps, or compressors, unlike hydraulic or pneumatic actuators.

They take up less space, as they don’t need additional components like air compressors or fluid reservoirs, making them more portable and flexible for various applications.

Since they can connect directly to a battery power source, electric linear actuators are often simpler to integrate into mobile or remote applications.

Electric linear actuators are known for their portability, flexibility, and reliability, making them ideal for diverse applications, from automotive to medical equipment, where precision, safety, and ease of installation are essential.

Sensors

A measurement system is composed of:

Input—-> Signal Processing Unit —-> Output

A sensor is a device that detects changes in environmental variables, such as heat, pressure, humidity, or movement and generates an output signal reflecting the measured quantity. The output signal produced by the sensor is proportional to the physical quantity it is measuring, making sensors critical components in any measurement system.

As the first element that interacts with environmental variables, sensors are essentially the “eyes and ears” of control and monitoring systems, converting physical data into forms that can be processed and analysed.

For instance, a thermocouple responds to heat at one of its junctions and produces an electrical output (voltage) that corresponds to the temperature. This output voltage can then be read by a voltmeter and displayed, making the temperature visible and measurable.

Calibration of Sensors: To ensure accurate measurements, sensors must be calibrated against a reference standard. Calibration aligns the sensor’s output with known values, reducing error and ensuring reliable data.

Sensors vs. Transducers: While sensors and transducers are closely related, they serve distinct roles:

A transducer converts one form of energy into another. For example, in the case of a thermocouple, the transducer converts temperature (thermal energy) into voltage (electrical energy).

A sensor, includes the transducer along with additional circuitry and components, such as display devices, to provide a usable output for interpretation.

In the thermocouple example, the thermocouple itself acts as the transducer by converting temperature into voltage. When paired with the necessary components, like a voltmeter and display circuitry, it becomes a complete temperature sensor capable of providing readable temperature measurements.

Sensors are fundamental in virtually all automated systems, from industrial machinery to environmental monitoring, where precise measurement and real-time data processing are required.

Types of Sensors

Sensors can be classified in several ways based on the quantity they measure, their energy requirements, signal output type, reversibility, and key performance characteristics. Here’s a detailed look at sensor classifications and characteristics:

Classification of Sensors Based on the Quantity Measured

Temperature Sensors are used to measure temperature changes, commonly used in HVAC, industrial processes, and medical devices. Examples include Resistance Temperature Detector (RTD), Thermistor, Thermocouple

Pressure Sensors are used to measure pressure in fluids or gases, widely used in hydraulic systems and weather stations. Examples include Bourdon Tube, Manometer, Diaphragms, Pressure Gauge

Force/Torque Sensors are used to measure force, load, or torque, essential in material testing and industrial automation. Examples include Strain Gauge, Load Cell

Speed/Position Sensors can be used to measure rotational speed and position, commonly used in motor controls, robotics, and conveyor systems. Examples include Tachometer, Encoder

Light Sensors are used to detect light intensity, used in cameras, street lighting, and security systems. Examples include Photo-Diode, Light Dependent Resistor (LDR)

Classification Based on Signal Output Type

Analog Sensors: Convert the physical quantity into a continuous (analog) signal, examples include thermocouples, RTD and Strain gauge. Useful in applications where the signal varies continuously, such as temperature or pressure measurement.

Digital Sensors: Produce output in the form of discrete pulses (digital signal), examples include encoders which produce pulses based on rotational position. Suitable for applications requiring digital readout, such as digital counters and robotic motion tracking.

Inverse Sensors. Some sensors have the unique property of being reversible, meaning they can sense a physical quantity and generate a corresponding output, but can also take the output form and convert it back to the original quantity.

Examples include Piezoelectric Crystals

As a sensor: They generate voltage when subjected to vibration.

As an actuator: When subjected to a varying voltage, they vibrate.

Application: Microphones (input sensing) and speakers (output generation) rely on this property of piezoelectric crystals.

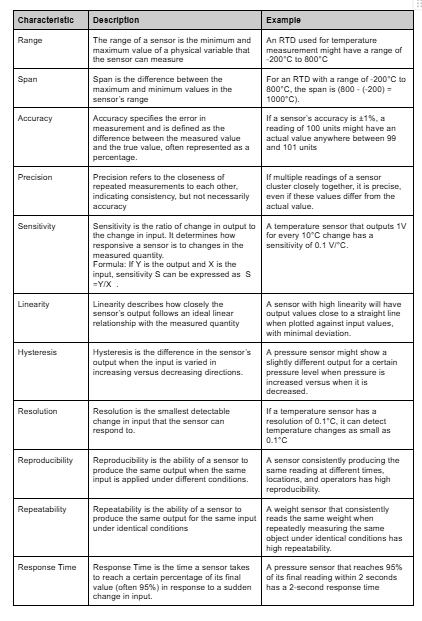

Characteristics of Sensors

The table below illustrates some of the key characteristics of sensors, which help determine their suitability, reliability, and performance in measurement systems:

Interested in our Electrical Engineering Courses?

At iLearn Engineering®, we offer a diverse range of online accredited engineering courses and qualifications to cater to different academic and career goals. Our courses are available in varying credit values and levels, ranging from 40 credit Engineering Diplomas to a 360 credit International Graduate Diploma

Short Courses (40 Credits)

A selection of our more popular 40 credit electrical diplomas…

Diploma in Electrical and Electronic Engineering

Diploma in Electrical Technology

Diploma in Renewable Energy (Electrical)

First Year of Undergraduate Electrical (Level 4 – 120 Credits)

Higher International Certificate in Electrical and Electronic Engineering

First Two Years of Undergraduate Electrical (Level 5 – 240 Credits)

Higher International Diploma in Electrical and Electronic Engineering.

Degree equivalent Graduate Diploma Electrical (Level 6 – 360 Credits)

International Graduate Diploma in Electrical and Electronic Engineering

All Electrical and Electronic Courses

You can read more about our selection of accredited online Electrical and Electronic Engineering courses here.

Complete Engineering Course Catalogue (all courses including industrial, mechanical and computer engineering)

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]