What is pressure in fluids, and how does it affect engineering problems?

In our previous articles, we looked at how to use various principles, such as moments of force, to solve engineering problems. In this article, we’re going to look into principles of fluids and how they affect engineering problems.

Pressure due to height of a fluid

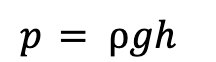

We can calculate the pressure exerted by a fluid at any given depth. Imagine a ‘tower’ of fluid above the point at which we want to measure. We will have the weight of this column of fluid acting on a point. The pressure, p, at a given depth can be calculated using the equation:

In this equation:

- p = pressure (Pa)

- ρ = density of the fluid (greek letter Rho, not to be confused with ‘p’ for pressure) (kg/m3)

- g = Gravitational acceleration (taken as 9.8m/s2 on Earth). (m/s2)

- h = The height of fluid above the point (depth of the point) (m)

Real life examples

Let’s have a look at some real life examples to see how this works. Firstly, let’s calculate the hydrostatic pressure exerted on a diver when they reach a depth of 30m. Take the density of water is 1000 kg/m³, and acceleration due to gravity is 9.8 m/s². Using the equation above, the pressure is 294 kPA.

Say we wanted to calculate the hydrostatic pressure exerted at the bottom of the Mariana trench, which is the deepest point in the earth’s ocean. Density of seawater is 1020 kg/m³, and acceleration due to gravity is 9.8 m/s². The depth of the Mariana trench is 11,034m! If we give our answer in units of bar, using the equation above we get 1,103bar.

Absolute pressure vs Gauge pressure

Air is a fluid, and it can also apply to pressure. This pressure of the air at sea level can be calculated as roughly 100kPA, which is also known as 1bar. This pressure is referred to as standard atmospheric pressure.

For context, the density of air at sea level is approximately 1.225 kg/m³, and it gradually reduces to 0 kg/m³ as we move to outer space.

Now, during our calculations above, we didn’t take into account this ‘additional’ pressure that is already present because of the atmosphere. It’s important to recognise the difference between these two terms:

- Absolute Pressure – this is the total pressure above that of a complete vacuum, in other words, total above zero pressure.

- Gauge Pressure – the pressure above that which is already present because of the atmosphere.

So, absolute pressure = gauge pressure + atmospheric pressure. If we look at our first real life example calculation from above, we can see that we were actually calculating the gauge pressure on the diver.

Let’s redo that calculation, rewording it slightly. Now we’re going to calculate both the gauge and absolute pressure exerted on a diver when reaching a depth of 30m. Again, the density of water is 1000 kg/m³, and acceleration due to gravity is 9.8 m/s². Atmospheric pressure is 101 kPa.

Using the original equation we saw right at the start of our article, we can calculate the gauge pressure as 294 kPa and the absolute pressure as 395 kPa.

Keep an eye out for our next article looking into how heat can affect engineering problems.

Interested in our courses?

You can read more about our selection of accredited online mechanical, electrical, civil and aerospace engineering courses here.

Check out individual courses pages below:

Diploma in Aerospace Structures

Diploma in Principles of Flight

Diploma in Aerodynamics, Propulsion and Space

Higher International Diploma in Mechanical Engineering

Higher International Certificate in Mechanical Engineering

Diploma in Mechanical Engineering

Diploma in Mechanical Technology

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]