Built to Hold: The Key Types of Welding Joints and When to Use Them

A weld joint, created by welding two components together, is a sturdy joint. The intersection of the edges or surfaces of two components that have been bonded together by welding is known as a weld joint.

Types of joints

For putting two pieces together, there are five fundamental types of joints that can be used. The five joint types are not just applicable to welding; they also hold true for other joining and fastening methods. The following are definitions of the five joint types:

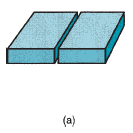

A butt joint. The parts are linked at their edges and lay in the same plane in this form of joint.

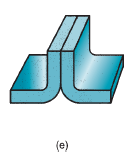

In the corner. The components of a corner joint are linked at the right angle’s corner.

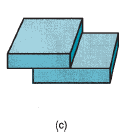

Knee joint. These two components of the joint overlap one another.

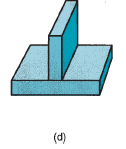

A tee joint. A tee junction has a part that is perpendicular to the other and roughly shaped like the letter “T.”

An edge joint. An edge joint is created by aligning the pieces so that at least one of their edges is parallel to the other.

Types of welds

It is appropriate to make a distinction between the type of junction and the type of weld. The geometry (joint type) and welding technique of different weld types vary.

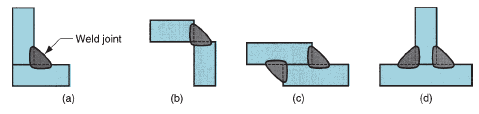

Fillet Weld: A fillet weld is employed to round off the edges of plates made by corner, lap, and tee joints. To create a cross section that resembles a right triangle, filler metal is employed. In both arc and oxy fuel welding, it is the most typical type of weld. The basic square edges of the pieces are employed since it only requires little edge treatment. Fillet welds can be single or double, continuous or intermittent (i.e., welded over the full length of the joint or with unwelded intervals along the length), and they can be welded on one side or both.

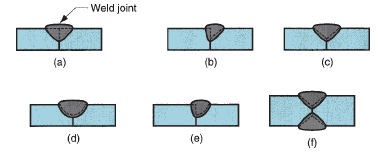

Groove weld: In order to enhance weld penetration, groove welds typically need for the pieces’ edges to be formed into a groove. Below are some of the shapes with grooves, including square, bevel, V, U, and J with single or double sides.

Typically, arc or oxy fuel welding is utilised to fill up the joint with filler metal. Even though it requires more processing, component edges are frequently prepared in order to strengthen the welded joint or in situations where thicker parts need to be welded. While utilised on all joint types except lap, groove welds are most frequently associated with a butt joint.

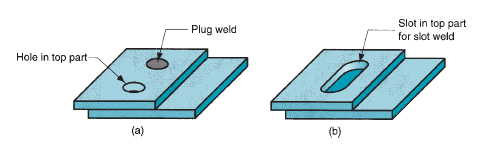

Plug welds and slot welds: Plug welds and slot welds join flat plates by creating one or more holes or slots in the top portion, which are then filled with filler metal to fuse the two pieces together.

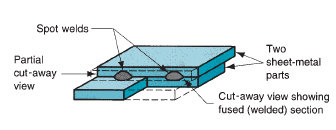

Spot weld: Spot welding is the small-scale joining of two sheets or plates’ surfaces. The pieces are normally joined using several spot welds. Resistance welding is most closely related to it.

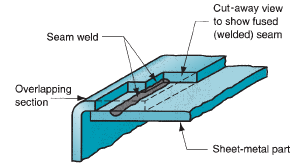

Seam weld: In contrast to a spot weld, a seam weld involves a portion that is fused more or less constantly between two sheets or plates.

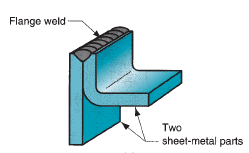

Flange weld: With at least one of the pieces being flanged, as shown below, a flange weld is created on the borders of two (or more) parts, typically formed of thin plate or sheet metal.

Surface weld: A surfacing weld is used to add filler metal to the surface of a base part in the form of one or more weld beads rather than to join the pieces together. Large sections of the base component can be covered by the weld beads by making several overlapping parallel passes. The intention is to give the surface a protective covering or to make the plate thicker.

Factors affecting material selection for welding operation

It’s essential to use a filler metal that has the necessary mechanical and chemical qualities for the operation and can endure the service conditions the weld faces.

When choosing a filler metal, keep these seven things in mind:

The raw material that will be joined: Most of the time, chemistry is required to combine two materials: What filler metal complements the base material the best? Mechanical parameters (such the tensile and yield strength) will match if the chemistry of the materials is the same. Operators who weld can be confident that their weld deposit will be as strong and durable as the base material.

Welding position: Operators who weld should rotate the component whenever possible so that it can be welded flat. The most cost-effective welding technique is always flat, next horizontal or vertical, and finally above.

Codes and specifications for regulations: What type of wire to use is frequently determined by job requirements. Otherwise, welders should carefully evaluate any potential servicing needs the welds may have. For instance, it is possible that the welds may rust, degrade, and corrode more quickly than the base material if a welder employs mild steel filler metal for applications exposed to severe conditions.

Design requirements: When choosing a filler metal, it’s crucial to make sure it satisfies or even surpasses the requirements of a joint design as described by the engineer’s welding configuration. For instance, it’s crucial that the arc characteristics are acceptable when welding thin materials because using a wire with deep penetration could result in the welder burning through.

Shielding gas: It’s crucial to confirm the compatibility of the shielding gas and filler metal employed in a given application. The impact of shielding gases on filler metal varies. For instance, the welding operator can transmit more of the filler metal’s chemistry into the weld deposit by mixing argon with carbon dioxide ( CO2). This combination results in consistent weld quality, good weld pool control, and less spatter. However, it also raises the possibility of cracking by transferring a richer chemistry from the filler metal into the weld deposit.

Heat treatment after welding: Before beginning to weld, specific steels and material thicknesses must be warmed to a specific temperature. Preheating enables a slow cooling of the component to prevent weld shrinkage problems and cracking. Similar to pre-weld heat treatment (PWHT), post-weld heat treatment is used to lessen stresses and gradually diminish residual heat introduced during welding, allowing the weld joint and base materials to regain the desired properties. It is crucial to pick a filler metal capable of making welds that react properly to the application of heat for materials that call for PWHT.

Welding equipment: The optimum filler metal depends on the kind and size of the machinery being utilised. The power source specifically needs to supply enough amperage for the size of wire being utilised for the task. If not enough amperage is available, it will be essential to either switch to a machine with a higher capacity or adjust the wire diameter, which could slow down output. The power source must also provide the appropriate welding current for the selected filler metal. Spatter and poor weld quality might result from welding in the incorrect current.

Material selection for welding operation

The kind of consumable used for welding depends on the desired job’s nature. Electrodes need to extract the required amount of energy to carry out welding operations. among the consumables are

Stick electrode: commonly known as welding rods, are required for considerable ability and welding rod knowledge. Stick rod performance depends on a number of factors, including storage methods, electrode diameter, and flux composition. With some fundamental understanding, one may minimise trouble and guarantee a better result in the welding procedures.

Fluxes: In order to stop the hot metals from oxidising, flux is frequently employed to create a shield of gas around the weld pool. Flux normally functions as a deoxidizer to stop porosity from developing in the weld pool. Welding consumables are filler metals and flux combined.The flux burns when an arc is struck, igniting a sequence of intricate chemical processes. Sheltering gas is released as the flux components burn in the welding arc, sheltering the molten weld pool from airborne contaminants. Flux creates slag when the weld pool cools to shield the weld metal from oxidation and avoid porosity in the weld bead.

Solid wires: This offers thorough root penetration and typically leaves little splatter.

Saw wires: These are consumables that produce exceptional productivity when combined with flux. It is crucial to consider how the wire, flux, and the metals to be welded will work together during the welding process. SAW wires are made to preserve good mechanical qualities after extended post weld heat treatment, unlike other wires that are less durable.

Flux cored wires: Flux-cored wires come in two varieties: gas-shielded and self-shielded. Flux-cored wires that are gas-shielded need an external source of shielding gas, and the slag is simple to clean up. When welding on thicker metals or in situations that require welding out of place, think about employing gas-shielded flux-cored wires. The flux layer on gas-shielded flux-cored wires solidifies more quickly than the liquid weld material. As a result, while welding overhead or vertically up, it makes a ledge to hold the molten pool.

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]