Adhesive Bonding Technology: Innovations in Joining Without Fasteners

A variety of materials, including metals, plastics, ceramics, wood, paper, and cardboard, can be joined together, both similarly and dissimilarly, by using adhesives in bonding and sealing applications.

Using an adhesive, two (or more) closely spaced parts are joined together by surface attachment. This technique is known as adhesion bonding. The glue acts as the filling substance to hold the components together. It is nonmetallic and typically a polymer. Adherends are the pieces being linked. Structural adhesives, which can create solid, long-lasting junctions between stiff, strong adherends, are the ones that engineering professionals are most interested in.

Adhesives are cured by various means to ensure it is strong enough for use.

Curing is the process by which the physical qualities of the adhesive are transformed from a liquid to a solid, typically through chemical reaction, to complete the surface connection of the pieces. It takes time for the adhesive to cure or harden; this period is known as the curing or setting time.

The strength of the adhesive and the strength of adhesion between the adhesive and each adhesive in an adhesive bonding process define joint strength.

Strength of adhesive bonded joints

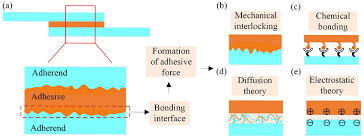

Several mechanisms contribute to the strength of the attachment, each of which is influenced by the specific adhesive and adherends:

Three types of bonding exist:

Chemical bonding, in which the adherent and adhesive combine to form a primary chemical bond;

Physical interactions, in which secondary bonding forces emerge between the atoms of the opposing surfaces;

Mechanical interlocking, in which the adherend’s surface roughness causes the hardened adhesive to become entangled or trapped in its minute surface asperities.

Adhesive joint design

In general, adhesive joins are not as durable as those made by welding, brazing, or soldering.

The following design guidelines can be used:

1. The joint contact area ought to be increased.

2. Adhesive joints should be constructed so that the applied stresses are of the shear and tension variety because these are the stresses that are strongest for adhesive joints

3. Adhesive bonded joints should be made to withstand less stress by avoiding stresses that cause cleavage or peeling

The diagram below shows typical joint designs for adhesive bonding that demonstrate these design ideas.

Types of adhesive

There are many commercial adhesives on the market. Three groups can be made out of them:

Natural: include gums, starch, dextrin, soy flour, and collagen, which are sourced from organic materials (such as plants and animals).This type of glue is typically only used in low-stress applications, including the binding of books, furniture, and cardboard cartons, or when a lot of surface area is needed (like with plywood).

Inorganic: The main components of inorganic adhesives are sodium silicate and magnesium oxychloride. They are reasonably inexpensive, but they also have a poor strength, a critical drawback for a structural glue.

Synthetic In manufacturing, synthetic adhesives are the most significant type. Many of them include a range of thermoplastic and thermosetting polymers.

Methods of applying adhesives

There are several methods for actually applying the glue to one or both part surfaces. Even if it isn’t comprehensive, the list below offers a representative sample of the methods employed in business:

Brushing – A stiff-bristled brush is used while brushing manually. Coatings frequently have uneven surfaces.

Flowing – which uses manually operated pressure-fed flow cannons, has more reliable control than brushing.

Manual rollers – adhesive is applied manually from a flat container using rollers akin to those used for painting.

Silk screening – To silk screen, the adhesive is brushed onto the component surface through the screen’s open spaces, coating only the desired places.

Spraying – For quick application over broad or challenging-to-reach regions, spraying uses an air-driven (or airless) spray gun.

Automatic applicators – Various automatic dispensers and nozzles for use in medium- and high-speed industrial applications are included in automatic applicators.

Roll coating – is a mechanical process in which a revolving roller picks up an adhesive coating by being partially submerged in a pan of liquid adhesive, which is then transferred to the work surface.

Benefits and drawbacks of adhesive bonding:

1. the process is applicable to a wide range of materials;

2. parts of various sizes and cross sections can be joined—fragile parts can be joined by adhesive bonding;

3. bonding occurs over the entire surface area of the joint, as opposed to in discrete spots or along seams as in fusion welding, thereby distributing stresses over the entire area;

4. some adhesives are flexible after bonding and are therefore tolerant of cyclical loading; and differences in thermal expansion of adherends;

5. low-temperature curing prevents damage to parts being joined;

6. sealing as well as bonding can be achieved; and

7. joint design is frequently simplified (for example, two flat surfaces can be joined without the need for special part features like screw holes).

Soldering Methods

Soldering is a joining method in which a filler metal is melted and spread by capillary action between the faying surfaces of the metal pieces being connected. This filler metal’s melting point (liquidus) should not be higher than 450oC (840F).

The base metals are not melted during the soldering process; instead, the filler metal wets and mixes with the base metal to create a metallurgical bond. Prior to soldering, surfaces must be thoroughly cleaned to remove any oxides, oils, etc. The faying surfaces need to be treated with a proper flux, and they are heated. Solder, a type of filler metal, is added to the connection and distributes itself among the pieces that fit together tightly.

Advantages of soldering

Soldering has several benefits over brazing and fusion welding, including

1. low energy input,

2. a wide range of heating options,

3. good electrical and thermal conductivity in the joint,

4. the ability to create airtight and liquid-tight seams for containers, and

5. ease of repair and rework.

Disadvantages of soldering

The two greatest drawbacks of soldering are:

1. limited joint strength unless mechanically reinforced

2. potential melting or weakening of the junction when used in high temperature environments.

Materials for soldering

The materials used in soldering are fluxes and solder. Both play a vital role in the joining process.

Solders: Due to their low melting points, tin and lead are the two metals used in the majority of solders. To gain effective control of the soldering process for a variety of applications, their alloys have a range of liquidus and solidus temperatures.

Soldering fluxes: There are two types of soldering fluxes:

Organic:Rosin, especially naturally occurring rosin like gum wood, which is not water soluble, is used to make organic fluxes. Water soluble components include alcohols, organic acids, and halogenated salts. The water soluble variety makes soldering cleanup easier. For connections in electronics and electrical systems, organic fluxes are most frequently utilised. At high soldering temperatures, they are frequently chemically reactive, although at ambient temperature, they are generally non corrosive.

inorganic : In situations where oxide films are an issue, inorganic fluxes, which include inorganic acids like muriatic acid and salts like mixtures of zinc and ammonium chlorides, are utilised to achieve quick and active fluxing. The salts are less corrosive than the acids but become active when melted.

Methods of soldering

There are several soldering techniques that can also be utilised for brazing, including torch soldering, furnace soldering, induction soldering, resistance soldering, dip soldering, and infrared soldering.

Other soldering methods, which are not applicable to brazing are:

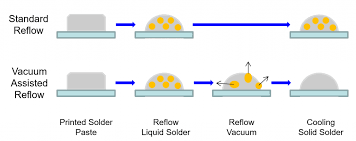

Reflow soldering: Electronics manufacturers frequently utilise this method to attach surface-mount components to printed circuit boards. During the procedure, locations on the board where electrical contacts are to be created between surface mount components and the copper circuit are covered with a solder paste made of solder powders in a flux binder. As the board is heated to melt the solder, mechanical and electrical bonds between the component leads and the copper on the circuit board are created. The components are then put on the paste places.

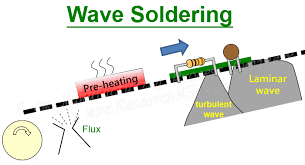

Wave soldering: Multiple lead wires can be soldered to a printed circuit board (PCB) using the automated technique known as wave soldering as the PCB moves over a wave of hot solder. The conventional configuration involves loading a PCB onto a conveyor and moving it through the wave-soldering apparatus while the lead wires of the electronic components have been attached to the board’s holes.

Hand soldering: A hot soldering iron is used manually for hand soldering. The working end of a soldering iron is a copper bit. It has four purposes: to heat the components being soldered, to melt the solder, to transport the molten solder to the connection, and to remove extra solder.

Brazing Technology

In the joining technique known as brazing, a filler metal is melted and dispersed between the faying surfaces of the metal components being joined by capillary action. Only the filler melts during brazing; the base metals do not.

Advantages of brazing

When compared to welding, brazing has a number of advantages:

1. any metals, including dissimilar metals, can be joined;

2. certain brazing methods can be executed quickly and consistently, enabling high cycle rates and automated production;

3. some methods allow for the simultaneous brazing of multiple joints;

4. brazing can be used to join thin-walled parts that cannot be welded;

5. less heat and power are generally needed than in fusion welding;

6. There is reduction in difficulties with the heat-affected zone in the base metal close to the joint.

7. Joint regions that are inaccessible by many welding procedures can be brazed because capillary action pulls the molten filler metal into the joint.

Disadvantages of brazing

Brazing has some drawbacks and limitations, such as the following:

1. joint strength is typically lower than that of a welded joint;

2. although a good brazed joint’s strength is greater than that of the filler metal, it is likely to be lower than that of the base metals;

3. high service temperatures may weaken a brazed joint; and

4. the colour of the metal in the brazed joint may not match the colour of the base metal parts,which could be an aesthetic drawback.

Brazing Application

In many different industries, brazing is a common production method, including the manufacturing of jewellery, electrical equipment, cutting tools, and automobiles (for example, to attach wires and cables, tubes, and shanks). In addition, brazing is used to join metal pipes and tubes in the chemical processing industry and by plumbing and heating companies. In almost all industries, the method is widely used for repair and maintenance work.

Brazing joints

There are typically two types of brazed joints:

butt – The strength of the traditional butt joint is compromised since there is little room for brazing

lap – Since lap joints can offer a sizable interface area between the pieces, they are more frequently employed in brazing.

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]