“Holding It Together: The Art and Science of Mechanical Fastenings”

A tool used to mechanically attach (or fasten) two or more things together is known as a mechanical fastener. Although there are many distinct kinds of mechanical fasteners, they can generally be split into two groups: permanent and non-permanent fastening.

The two categories of non-permanent fasteners, which allow for repeated assembly and disassembly of parts, are as follows:

1.General fasteners, frequently connected to shafts, such as keys, pins, retaining rings, etc.

2.fasteners with threads, including bolts, screws, studs, setscrews, etc.

Since they are the easiest to remove and reuse, they are the most popular kind of non-permanent fasteners. However, since removing rivets will ruin them, rivets are regarded as permanent fasteners.

Screwed (Threaded) Fastenings

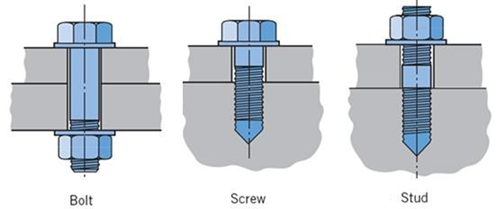

The basic tools for assembling components are threaded fasteners, which are often divided into three major groups as depicted in the figure:

Bolts: A bolt is connected with a nut and has a head on one end and threads on the other.

Screws: Like bolts, screws have a head on one end and threads on the other end. They are used to connect two matching parts together. However, screws can be constructed with slotted heads, and they often have longer threads than bolts.

Studs: A stud is a rod that connects two matching components by having threads on both ends. On one end, a nut may be used.

Thread Standards and Definitions

Mechanical fasteners are standardised in every way. These details are published in : ISO Standards Handbook: Fasteners and screw threads.

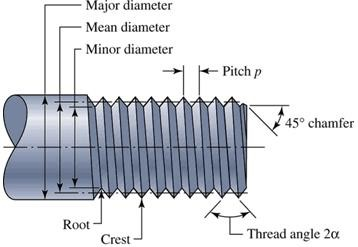

The diagram below shows the terminology for screw threads:

The following should be noted:

The greatest diameter of the screw thread is called the major diameter (D, d).

The screw thread’s minor diameter (D1, d1), also known as “root diameter, is its smallest diameter.

Mean diameter (D2, d2), commonly known as “pitch diameter,” is the average screw thread diameter when taking into account the threads’ fictitious maximum height.

The spacing between neighbouring threads, measured parallel to the thread axis, is known as pitch (p).

The angle formed by the mating faces of two consecutive threads is known as the thread angle (𝛼).

Unless otherwise stated, all threads are typically right-handed. Right-handed screws advance when rotated in the direction of the curled right-hand fingers.

There are two main standards for bolt and screw threads: (ISO) Metric and (ANSI) Unified. The thread angle in both standards is 60 degrees.

Internal and External Threads

External Thread: Bolt and screw threads are examples of external threads, which are on the exterior of a member. It is simpler to insert a screw into a hole or nut when the screw thread end has a chamfer. An external thread is usually cut using a die such as the one shown above, or a lathe.

Internal Thread:The threads of nuts and holes are examples of internal threads because they are on the inside of a member. In order to facilitate the engagement of the screw, threaded holes typically feature a chamfer on the side from which the screw will enter. Typically, a tap is used to cut an internal thread, as demonstrated below

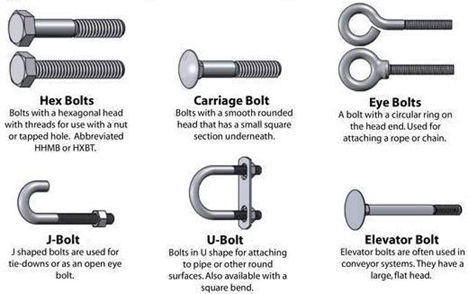

Different types of screws, bolts and rivets

There are numerous varieties of bolts and screws, and each is appropriate for a variety of uses. Some of the most popular varieties of bolts and screws are depicted below:

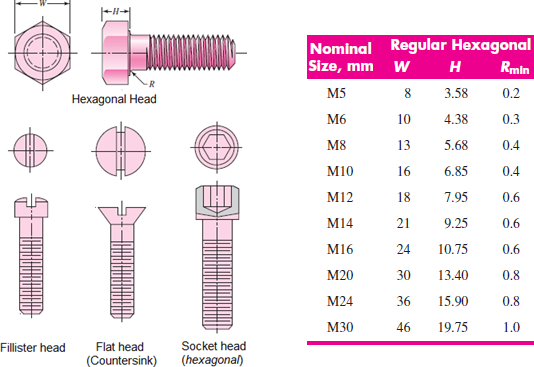

There are standards and common practices related to all aspects of the form and geometry of threaded fasteners. Bolts mostly have hexagonal heads and the figure shows some of the common head styles that are used.

All head measurements are uniform, and they are typically listed in tables based on nominal size. The dimensions of a normal hexagonal head bolt’s standard head are listed in the table below

Rivets : Rivets are regarded as permanent fasteners, unlike removable (or nonpermanent) fasteners, such as bolts and screws. Rivets are generally used to hold plates or sheet metal together.

Rivets are used in a very wide variety of applications ranging from aircraft structures to civil steel structures to automobiles to boats and ships and even clothing. There are many different types of rivets where each type is more suitable for certain types of applications. The most common and distinct two types of rivets are solid rivets and pop rivets.

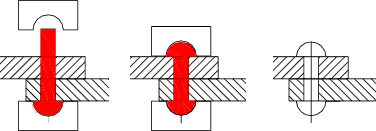

One of the oldest and most dependable types of rivets are solid rivets. They just have a single head on a cylindrical shank. The other end of the rivet is bent with a hammer or rivet gun as shown below once the shank has been put within the hole.

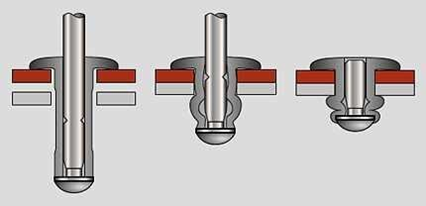

The most popular form of rivet for general-purpose applications is the pop rivet, commonly known as a blind rivet. Pop rivets may be installed quickly and easily, and one of the main benefits of using them is that you don’t need access to all sides of the assembly to do so. Pop rivets have a mandrel through the middle and are tubular in shape. A unique tool is used to draw the mandrel into the rivet after the rivet has been introduced into the hole that has been drilled through the parts that will be bonded. As shown in the image, this causes the rivet’s blind end to expand after which the mandrel disengages. Such rivets, however, are not very dependable and are not able to withstand heavy loads.

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]