Why Limits and Fits Matter When Choosing Fasteners

Introduction

Fasteners, such as bolts, screws, rivets, and pins, are fundamental components in almost every engineered product, from cars and airplanes to machinery and electronics. While they may seem simple, choosing the correct fastener is a highly technical process that must consider material properties, loading conditions, environmental factors, and critically, the limits and fits of the fastened parts.

The limits and fits system governs how precisely two mating components align and interact, which directly affects the performance and reliability of the fastening. If a bolt fits too loosely, it can lead to vibration, wear, or structural failure. If it fits too tightly, it may cause stress concentrations, material deformation, or even assembly issues. This is especially important in high-precision or safety-critical applications, such as aerospace structures or pressure vessels.

When selecting fasteners, engineers must consider the tolerance range of both the hole and the fastener shaft to ensure the desired fit, whether it’s a clearance fit for easy assembly, an interference fit for secure locking, or a transition fit for controlled positioning. Understanding how limits and fits influence these choices helps prevent mechanical issues, reduce manufacturing costs, and ensure long-term durability.

What is a fastener?

A fastener is a piece of equipment used to mechanically connect two or more things. Fasteners can typically be permanent or non-permanent, but they are frequently employed to construct joints that are not permanent. This makes it possible to remove or disassemble the joints without harming the linked components. Other methods of joining, like welding, produce a permanent joint.

Due to their simplicity of installation and removal as needed, threaded fasteners are the most widely and often used for part assembly. Two important standards, ANSI (Unified) and ISO (Metric), are used to standardise fastener threads. Depending on the application, their threads can either be right- or left-handed, but the majority are right-hand threaded. Bolts, screws, and studs are the three basic types of threaded fasteners.

Application of fit fasteners

To increase the fatigue life of metallic structures, interference fit fasteners are routinely employed. Installing an interference fit fastener in metal causes a tiny area to flex, creating a compressive stress field that is advantageous when fatigue loading is largely in tension.

The ability to “lock up” the structure and stop any movement at the joint (known as ratcheting) during fatigue loading is one potential advantage of using some interference fit fasteners in composite structures.

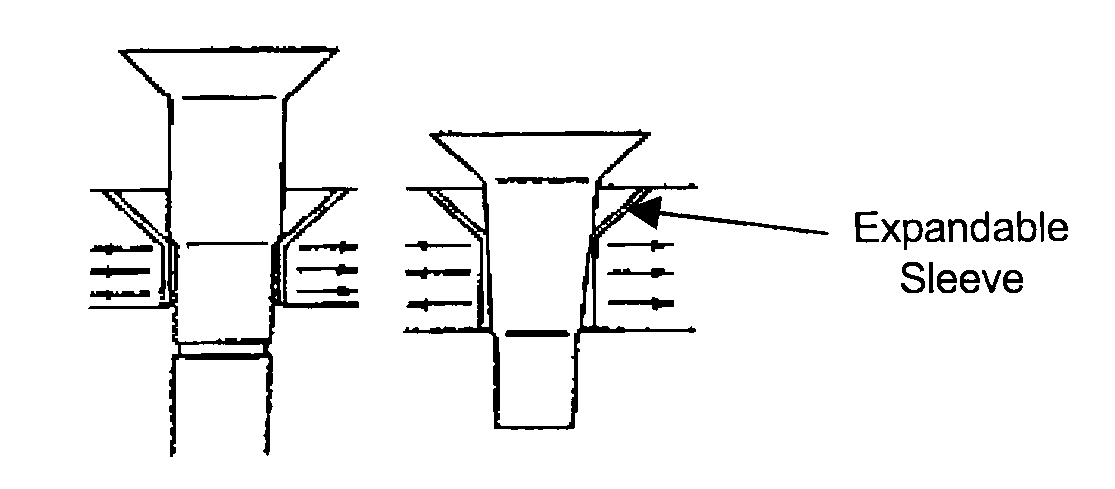

Utilising unique sleeve-type interference fit fasteners will prevent interlaminar delamination’s and cracking in composite materials.

Interference fit fasteners vs clearance fit fasteners

Interference fit fasteners have a number of possible benefits in composite structures:

1. less joint deflection;

2. less fastener cocking, which lowers localised bearing stresses and locks up the structure to prevent ratcheting during fatigue; and

3. lower assembly costs when interference fits are needed in metallic structures (the composite requires no disassembly and ream operation).

Allowance refers to the variation between shaft and hole sizes in a particular type of fit.

The distinction between clearance fit and interference fit is explained by allowance. Negative allowance in a fit specifies the interference or force fit, whereas positive allowance specifies the clearance fit.

Contrary to transition-fit (or close-tolerance) and most definitely clearance-fit fasteners, interference-fit fasteners will provide longer fatigue lifetimes to aeronautical structures. But due to several installation challenges with applying these fasteners into the proper holes in the structure layers, interference-fit fasteners are used less frequently in real industrial settings. Additionally, questions may be raised about whether any realistic interference-fit installation approach actually maintains the fatigue advantage (or even if the installation process actually causes a fatigue disadvantage).

It should be noted that fastener holes serve as stress concentrators and may cause the emergence of fresh fatigue cracks.

The use of bolt assemblies in industry is enormous. An interference fit fastener can take the place of the bolt assembly when it is situated in a crucial area. In that situation, the screw has a cylindrical component that is inserted into a hole with a smaller diameter. The interference in size at their interface diameter causes a radial pressure that locks both pieces together in addition to the tightening force. It has been demonstrated that this technique tends to delay cracks coming from fastener holes.

Because of this, interference fit fasteners are frequently used in aerospace and space applications. Unfortunately, there are rare instances when the tightening load can be lost at the interference diameter and a gap can develop between the screw head and the plate, especially when the friction factor and interference level are too high. Such a situation is obviously prohibited in industrial use.

When free movement is required and some play is desired, clearance fits enable loose mating. Where elements should be able to slip in and out without interference and where alignment can be loosely directed but doesn’t need to be precise, clearance fits are asked for. Bolt or shaft holes that allow one element to freely glide through another feature are examples of clearance fits.

However, a clearance fit is substantially looser than an interference fit. The interference fit, which is also known as a press fit or friction fit, requires some force to unite two components. An interference fit can be used to press a bushing, bearing, dowel pin, or other objects into their mate components. Once coupled, this forms a relatively strong union that would require a lot of force or perhaps even some mechanical action to separate.

Effects of limits and fits on fastener application

Bolts

Clearance holes are made to prevent the head of a bolt from going through while allowing the shank to do so without obstruction. The amount of clearance required relies on the precision required for the assembly’s position as well as the dimensional tolerance of the components

The majority of bolt holes are manufactured with “standard” clearance and are thought to fit well. A typical fit allows for a small amount of misalignment while still allowing for reasonably accurate positioning of assembled components.

Larger holes are thought to be a loose fit since the bolt has more room to move and has greater clearance for the bolt shank. If the components you’re assembling have wide tolerances, you can use a larger hole to accommodate more alignment variation.

Close fitting clearance holes have just enough room for the bolt shank and allow for very little component misalignment. If the components you are constructing have pretty close tolerances, you can use this fit. The best positioning precision can be achieved without the use of additional locating hardware when there is a close fit.

Screws

Objects with tapped (internally threaded) holes are intended to be fastened using screws. Although their heads and shanks come in a variety of sizes, forms, and materials, they often feature a pointy tip.

The self-tapping screw, which is made to cut its own threads as it is assembled rather than being driven into a hole that has already been tapped, is one unusual fastener. Self-tapping screws are typically put in pilot holes that are undersized such that they are less than the minimum diameter of the screw since they perform best in soft materials like wood and plastic

Nuts

Normally attached to the other end of a bolt that has been inserted into a clearance hole, nuts have female threads. Lock nuts, wing nuts, and T-slot nuts are a few shapes that have particular uses, although the hexagon shape is the most common. Hex nuts are torqued with a wrench to create tensile force between the nut and the bottom face of the bolt head when they sit against the surface of the assembled product (or a washer).

Washers

Despite not having a thread, washers are frequently used with fasteners that have one. The least expensive and most popular type of washers are flat washers. They have an outer diameter that is larger than the bolt head and a clearance hole for the bolt shank. They are rather thin.

By increasing the surface area between the bolt head (or nut, if it is constructed on the other side) and the item it is seated against, washers primarily serve to more equally distribute the clamping force. This is especially crucial if you’re putting together delicate or easily broken goods. It is more probable to harm a bolt than a washer if a significant clamping force is applied to a washer’s larger surface area. This is because bolt heads have a tiny surface area.

If the bolt shank is excessively long, washers can be used under the bolt head as spacers. The use of assemblies vibrating at frequencies that release fasteners is another example. Vibration-damping washers are made to absorb some of the vibration in these circumstances to stop loosening.

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]