Smooth Operators: The Crucial Role of Lubricants and Lubrication Systems in Machinery.

Introduction

In the world of machinery and mechanical systems, motion is everything. From industrial turbines and automotive engines to manufacturing robots and household appliances, countless machines rely on the smooth and efficient interaction of moving parts. However, this motion comes at a cost: friction, heat, and wear. Left unchecked, these forces can lead to significant damage, energy inefficiency, and costly downtime.

That’s where lubricants and lubrication systems come into play.

Lubricants serve as protective agents, creating a thin film between moving surfaces to reduce friction, dissipate heat, and minimize wear. They are the unsung heroes that ensure machines operate reliably, efficiently, and for longer periods. But lubrication isn’t just about applying oil or grease, it’s a carefully engineered process, often involving automated systems, precise formulations, and scheduled maintenance strategies.

This blog explores the essential role of lubricants and lubrication systems in modern machinery. We’ll delve into their functions, the different types of lubricants available, the technologies behind lubrication systems, and why proper lubrication is critical to machinery performance and longevity. Whether you’re an engineer, technician, or simply curious about how machines keep running smoothly, this guide will offer valuable insights into one of engineering’s most vital support systems.

What is a lubricant?

A lubricant is a gas, liquid or solid that is used to prevent contact of parts in relative motion, reducing friction and wear. Other important functions of lubricants are machine cooling, removal of contaminants, rust prevention, sealing out of dirt and power transmission as in hydraulics.

Lubricants reduce friction by forming a layer between two surfaces. Static friction resists relative movement between two objects and must be overcome before movement can take place. Dynamic friction is caused by two objects rubbing against each other and sliding friction is caused by two objects sliding over each other.

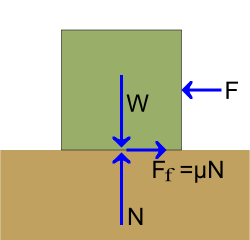

The diagram shows two objects in contact and it can be seen that the force tending to move the body is resisted by the frictional force Ff .The friction force is given by:

Ff = μN

where μ is the coefficient of friction, N is the normal force (reaction force due to the weight, W, of the object resting on the surface).

The coefficient of friction is determined by the material used:

For dry steel on steel μ = 0.8 whereas for lubricated steel on steel μ = 0.8. Therefore, we can see from this simple example that the introduction of a lubricant reduces the coefficient of friction, which will then reduce the friction force, and hence enable the object to slide more easily (less effort).

Types of Lubricants

Oils

Oils are thin liquids made of long polymer hydrocarbons chains, with additives for various

extra properties. Common additives include antioxidants to keep the oil from oxidizing, corrosion inhibitors to prevent parts from corroding, and detergents to keep deposits from forming. These long chains are hard to squeeze out from between surfaces, making oils useful as a slippery barrier between them.

In general:

- Mineral oils are derived from hydrocarbons have good lubricating properties but they are not food safe

- Synthetic food grade oils used where food contamination must be avoided but lubrication properties may not be as good as mineral oils

Oils come in different “weights” (such as 5W or 10W), which correspond to viscosity. The lower the number, the thinner the oil, and the more easily it will flow.

Uses: Hinges, bearings, tool maintenance, sharpening blades

Types: Motor oil, 3-in-1 oil, sewing machine oil, bar and chain oil

Use When:

• You want to lubricate something without the resistance inherent in using grease

• You need lubrication to wick into a small space, without having to take anything apart

Don’t Use When:

• The surfaces being lubricated are exposed to dust or dirt, which can eventually gum up and cause more friction

• You need to keep things around the surfaces clean, because oils are low in viscosity and thus tend to drip and run

• The surfaces are exposed to water or anything that can wash the oil away.

(while oil can help make things water resistant, it can also absorb water over time. The more water that absorbs into the oil, the lower its adhesion will be, causing it to wash off of the very parts that need lubrication.)

In general the higher the viscosity the thicker the oil. Multigrade oils perform differently at different temperatures, For example, 10W40 flows like a 10 at low temperature and a 40 at high temperature (W stands for winter). We must also be careful not to over lubricate machines because heat and pressure breaks down lubricants and seals.

Another important factor in oil selection and storage is the flash point of oil. The flash point of a flammable substance is the lowest temperature that the vapour of the substance will ignite. This is important when considering the best lubricant for machines with high working temperatures such as oven and furnace fans for instance.

Grease

Greases are made by using oil (typically mineral oil) and mixing it with thickeners (such as lithium-based soaps). They may also contain additional lubricating particles, such as graphite, molybdenum disulfide, or polytetrafluoroethylene (PTFE, aka teflon). Greases combine the lubricating properties of oils with added stickiness, allowing the lubricant to adhere to the surfaces better. Greases can even act as a barrier, protecting the surfaces from contaminants that can corrode or damage them. Like oils, greases come in a range of consistencies, from ketchup-thin to thick like cheddar cheese.

One disadvantage to grease is that because it is so ‘thick and sticky’, it can cause resistance in small or fast-moving mechanisms.

Uses: Gears, bearings, chains, linkages

Types: White lithium grease, marine grease, silicone grease

Use When:

• You need lubrication to stay put and stick to surfaces for a long time

• You want to seal out contaminants such as water or dust

• You use a machine so infrequently that you may forget to oil it

Don’t Use When:

• You have fine or fast-moving mechanisms where thick grease would create too much resistance

• You don’t want a mess. When parts move, they can fling grease around, so it may not be the best option for keeping things clean.

In general, greases are used where a mechanism can only be lubricated infrequently and where oils would not stay in position. Grease acts as a sealant to prevent ingress of water and dust. Lithium based greases are most common up to a temperature of 120 degrees Celsius. Teflon is added to some greases to improve lubrication properties.

Some greases are labelled EP for increased pressure use (these contain Graphite or Molybdenum Disulphide). Silicone grease is not oil based and does not attack rubber seals

Silicone and PTFE based synthetic lubricants are used for food applications

Dry Lubricants

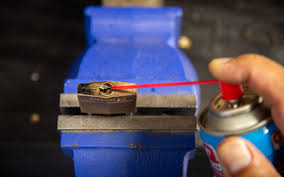

Dry lubricants are made up of lubricating particles such as graphite, molybdenum disulfide, silicone, or PTFE. At the molecular level, these particles are super slippery, so they reduce the friction between surfaces in contact with one another. It’s common to find these lubricants in spray form, where they are mixed with water, alcohol, or some other solvent that will evaporate away after application, leaving behind a thin film.

Uses: 3D printer rails, threaded rods, locks, hinges

Types: Graphite powder or spray, molybdenum disulfide spray, (dry) silicone spray, PTFE spray

Use When:

• You have tiny parts that shouldn’t be blocked by grease or oil that will attract dust

• You need to keep surrounding surfaces clean

• Your surfaces are exposed to extremely high heat or pressure, which would typically oxidize oils

Don’t Use When:

• Your surfaces are exposed to solvents or other liquids that can wash them away

Environmental Issues

In the UK it is illegal to pour lubricants down the drain. Lubricants must be disposed of at registered waste disposal centres. It is common to have a waste oil tank on site that is emptied by a registered contractor. Care must be taken when disposing or storing machines that lubricants do not leak and contaminate water sources. Prosecution can result if contamination takes place.

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]