Sealing the Deal: Principles and Applications of Mechanical Seals in Engineering.

Introduction

In countless industrial and engineering systems, keeping fluids contained while allowing rotating components to function freely is a critical challenge. From pumps and compressors to mixers and reactors, the demand for effective sealing solutions is essential, not only to maintain performance but also to ensure safety, environmental protection, and equipment longevity.

Enter the mechanical seal, a compact but powerful device designed to prevent leakage where a rotating shaft passes through a stationary housing. Unlike traditional packing methods, mechanical seals offer high reliability, lower maintenance, and superior performance in harsh operating conditions. Their design allows them to withstand pressure, temperature fluctuations, and corrosive or abrasive fluids, all while maintaining a tight seal.

This blog explores the principles of operation of mechanical seals, including how they create a sealing interface and manage friction and wear. We’ll also discuss their typical applications across industries such as oil and gas, chemical processing, water treatment, and food manufacturing. Whether you’re a student of mechanical engineering or a professional in plant maintenance, understanding how mechanical seals function is fundamental to mastering modern fluid-handling equipment.

Mechanical seals are simply another means of controlling leakage of a process where other means are deemed to be less capable of performing the task adequately.

Seals for Static Applications

In static applications, there is no relative motion between the members being sealed.

‘O’-Rings

‘O’ rings are very common seals for static application, but they also have application in slow rotating and reciprocating systems.

O Rings are made from rubber and can easily be twisted or damaged on installation. An example of these seals can be seen below.

At installation it is advisable to place a temporary sleeve over keyways and screw threads to avoid damage. Such seals also tend to form flats when worn

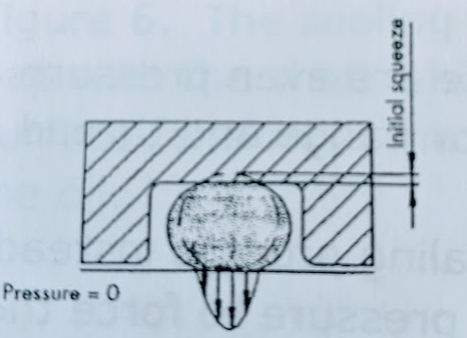

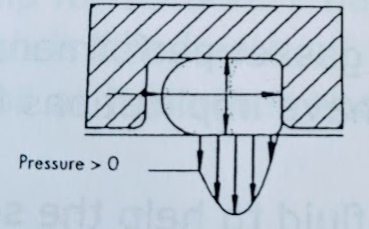

The sealing mechanism of the ‘O’ ring is illustrated below.

The pre-compression of the ring ensures sealing when there is no pressure.

When pressure is applied the ring is forced against the gap and seals it.

Care must be taken to avoid extrusion of the ring.

Care can be taken by:

- By keeping clearances low

- By having rectangular grooves

- Using an anti-extrusion ring at very high pressure,

The required dimensions of the grooves are given in catalogues and tolerances must be rigorously maintained. Of particular importance are the radii on the shoulders of the groove; too large and they will aid extrusion, too small and they will damage the ring. Grooves must be burr free.

Gaskets

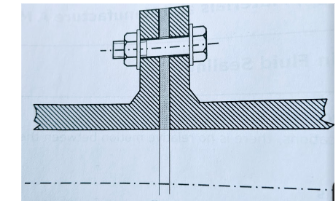

Where there is plenty of room in applications such as pipe flanges, cylinder heads, etc. gaskets are used extensively. The gasket material is compressed by the surfaces. The bolts must be pre-tensioned such that full pressure, when applied, will not relieve the pressure on the gasket.

Gaskets and O rings can be found in various shapes and materials as seen in figure 6 below such as paper, cork, rubber, rubber bonded cork, asbestos, plastic and metals.

Gaskets are generally die cut ready to fit. Bolts may be torqued using a wrench and liquid sealant are sometimes used to aid the seal.

Design Considerations

Flat gaskets deform and creep and hence become less effective with time. Hard metallic gaskets are used for small contact area joints. The fluid pressure when applied will decrease the contact pressure.

For high temperatures, metallic-fibre spiral gaskets are used.

The requirements for good gasket performance are even pressure and clean flat surfaces. These are implications for flange and thread design.

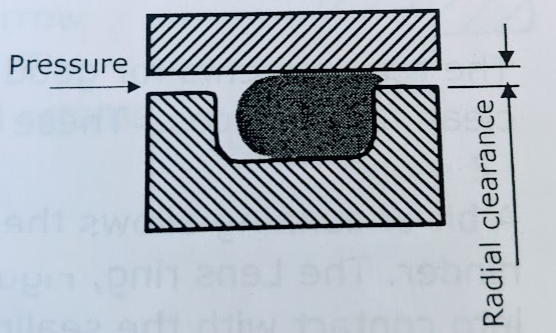

Using some cunning engineering actually allows the fluid to help the sealing process instead of hinder. The lens ring, uses the fluid pressure to force the ring into contact with the sealing faces on the flange.

Seals for Rotating shafts

Mechanical seals can be used to seal a myriad of different products on an equally vast array of equipment. Let us initially explore the need to seal a liquid in a centrifugal pump.

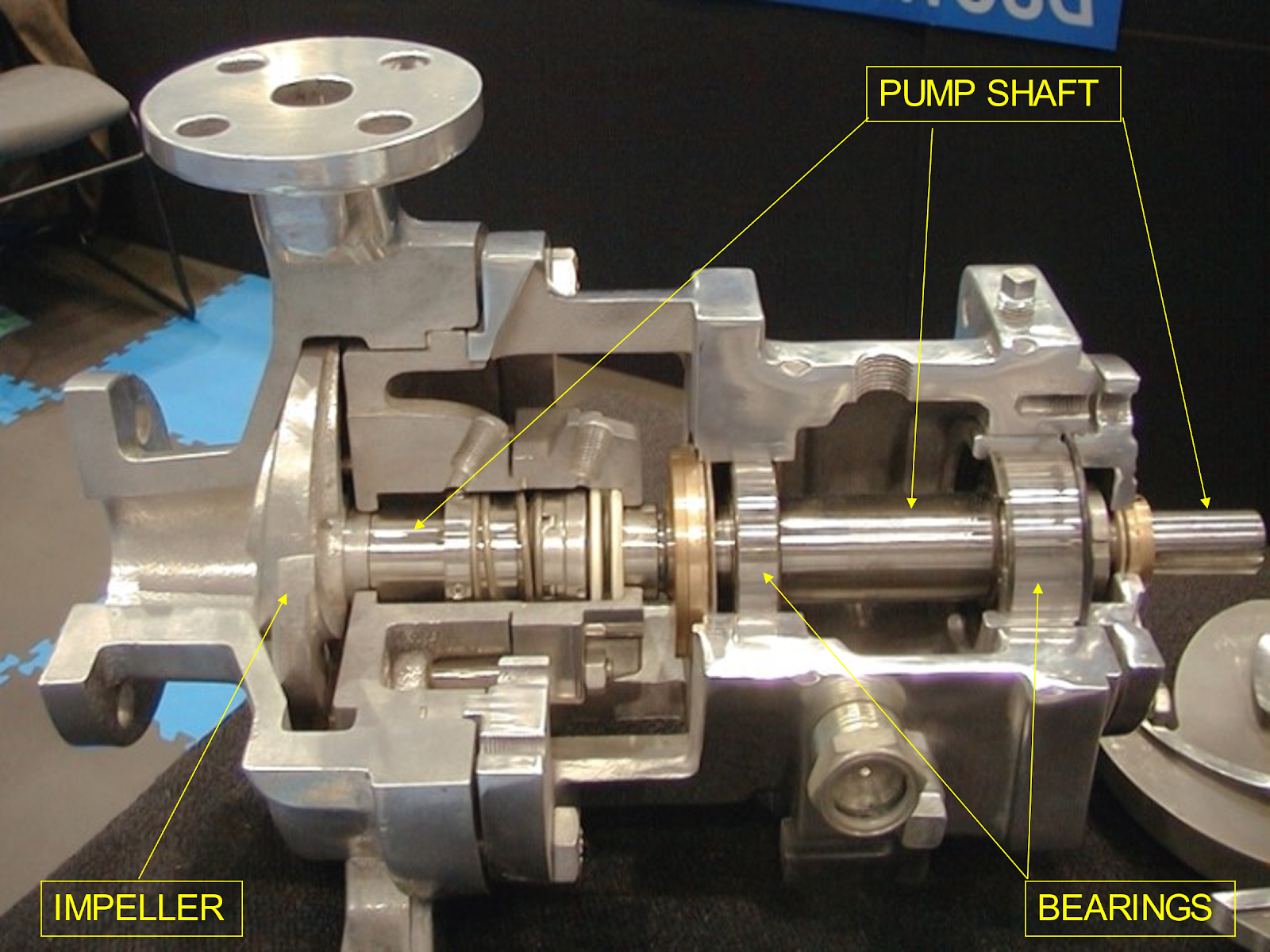

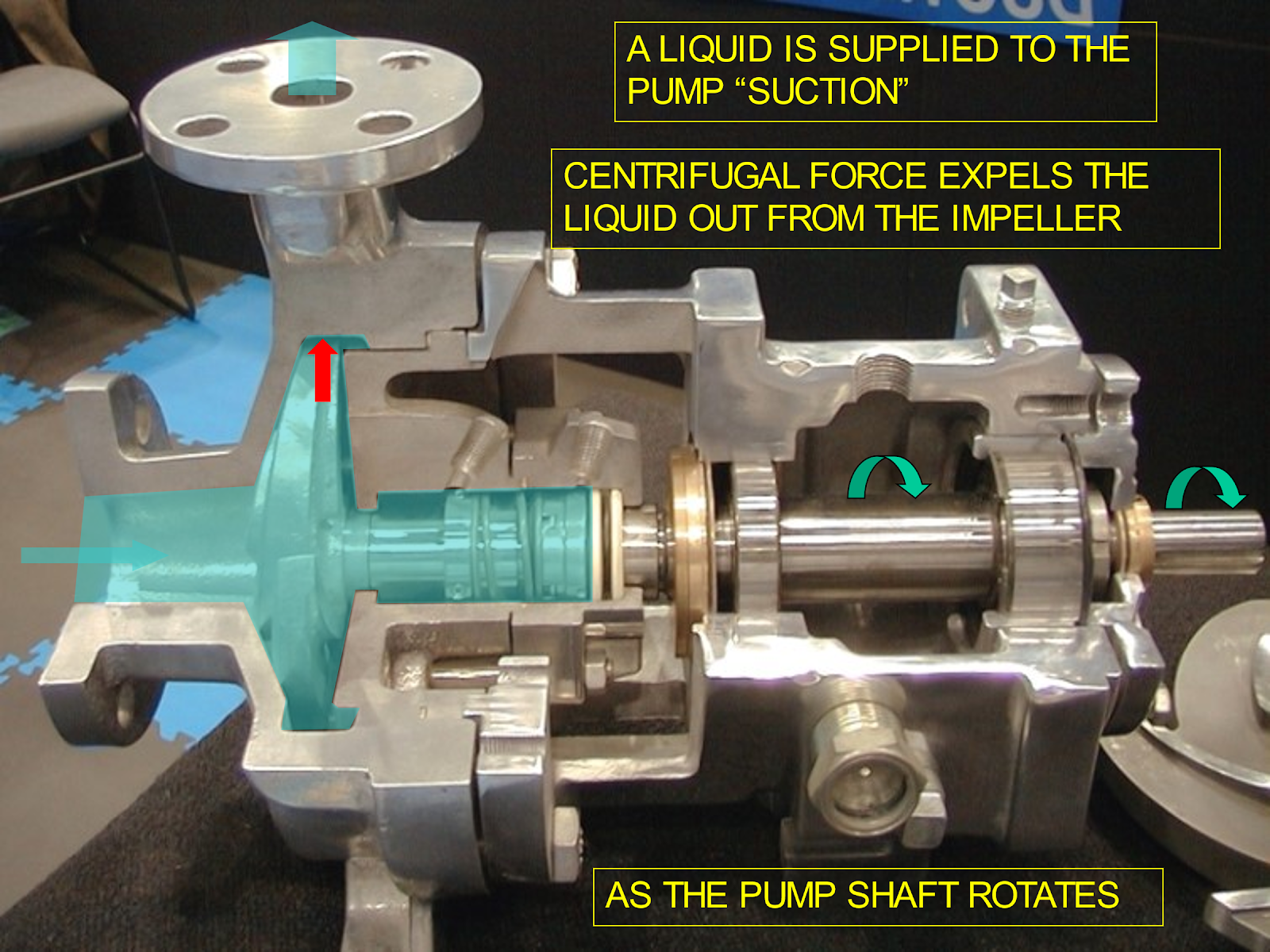

A centrifugal pump is simply a shaft, suspended on bearings with an impeller attached to one end. The impeller is encased in a housing that is filled with a liquid. As the shaft is rotated, centrifugal force expels the liquid out through an orifice, where it is typically piped into a process or another collection point. As the expelled liquid exits the case, additional liquid is added to the case so that a flow develops.

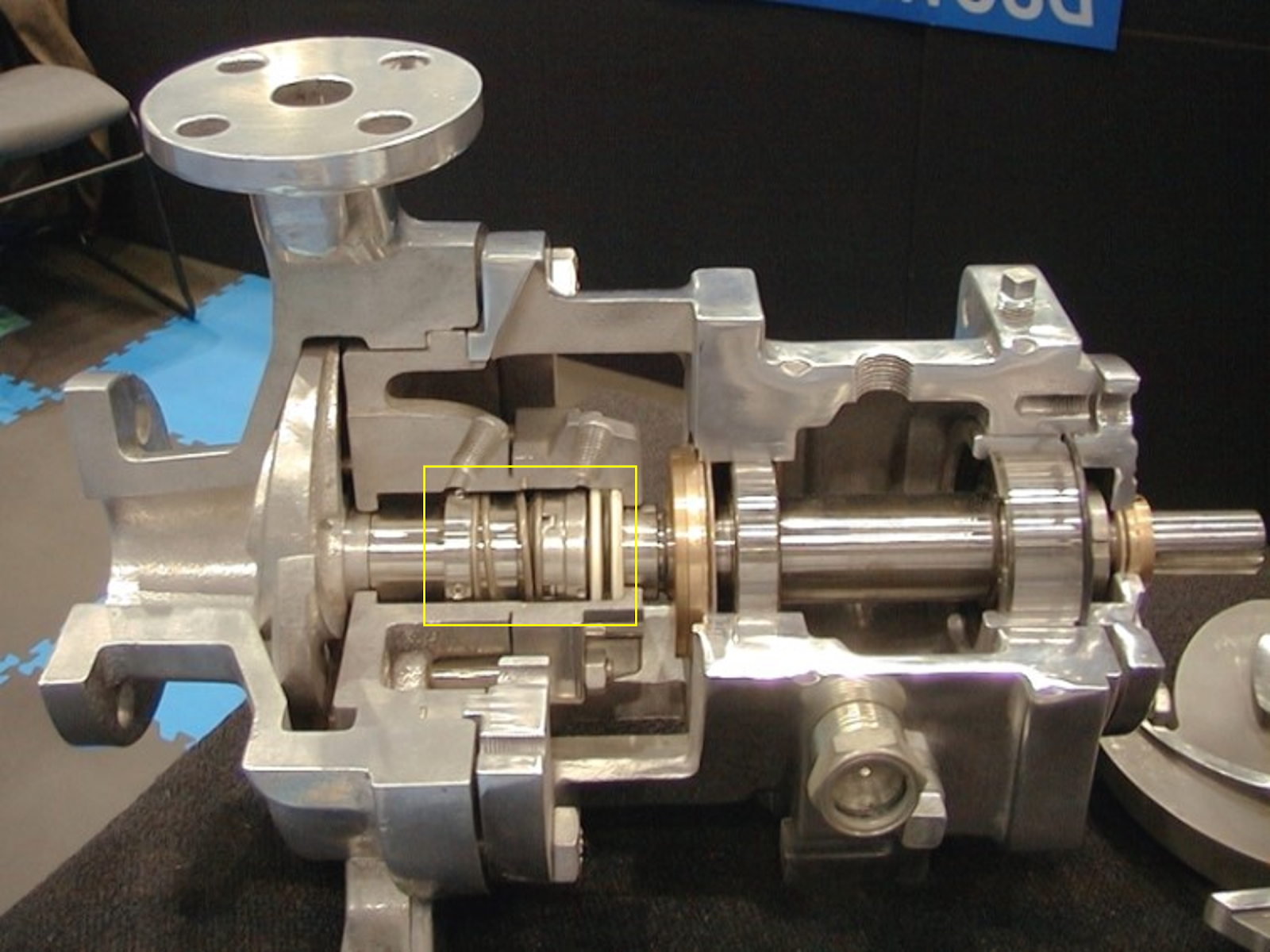

The diagram below shows a typical centrifugal pump. The force of the expelled liquid creates pressure. This liquid under pressure will seek areas of lower pressure. This is a known physical principle of hydraulics. Some form of seal must be applied to keep liquid from leaking around the shaft at the point where it enters the case to drive the impeller. This is where our mechanical seal comes into play.

Fluid flow through the pump impellor.

The mechanical seal shown in the pump photograph above in the yellow box, it is probably the most widely recognized and also most common mechanical seal used in general service, low pressure applications.

The assembly shown in the pump is configured with a ceramic “O-ring” type stationary seat and can be seen below.

Mechanical seals were originally designed to lend a greater sealing capability than could be achieved using common packing. Before the advent of mechanical seals, pump users relied primarily on “rope” or braided style packing to achieve a “seal” around the shaft. A series of pieces or “rings” were installed into the pump “stuffing box” and they were compressed tightly so that they created a difficult leak path for the liquid to negotiate in order to leak to the atmosphere.

Early packing styles did not seal very well. In fact, until recently, braided packing styles required varying amounts of leakage for lubrication. If leakage was not permitted to occur, the packing would literally “burn up” and often cause severe damage to the pump shaft. Even with adequate leakage for lubrication, pump shaft wear was a commonly expected occurrence and as the shaft wore it would in turn, cause poor shaft packing life.

As leakage becomes more excessive, the gland is tightened to reduce leakage. With the introduction of mechanical seals, this leakage could be controlled to a much greater degree.

It is a fact, all mechanical seals leak. Like packing, the mechanical seal “faces” must also be lubricated. With proper application and design however, the leakage is so minute that actual droplets of liquid are not detected. Instead, the lubricating liquid will vaporize as it crosses the seal faces and the leakage is a gas or vapor.

The mechanical seal faces are obviously the most critical sealing point of a mechanical seal assembly. Although the faces can be manufactured from a myriad of different materials, one is typically carbon, while the other is usually a hard material. (i.e. Alox (Aluminum Oxide Ceramic), Tungsten Carbide, Silicon Carbide, etc.) In order for a “seal” to be achieved, the faces must be very flat. This is achieved by machining the faces, then “lapping” them to a fine finish.

Low Pressure Rotating Applications

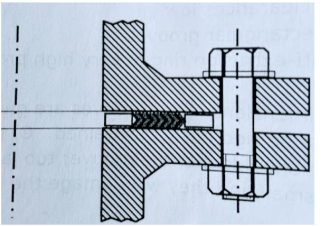

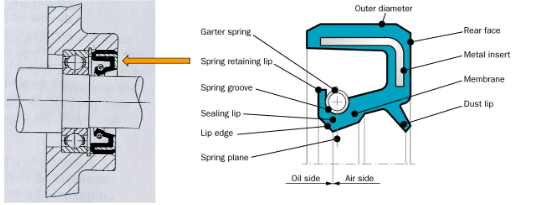

The most common form of low pressure fluid seal for rotating shafts is the metal insert lip seal, in which a flexible spring loaded sealing lip bears lightly onto the shaft sealing surface. The seal must be mounted such that the fluid pressure acts on the spring side and increases the sealing pressure. A typical installation is slow below.

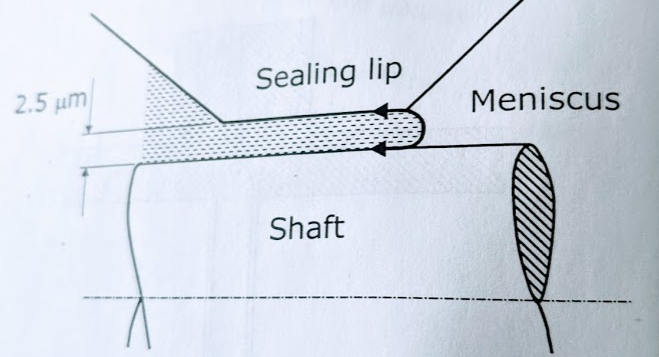

Fluid sealing – The mechanism of fluid sealing is shown below. The sealing lip forms a very narrow gap with the shaft which is filled with oil. The surface tension of the oil at the outer end retains the oil.

Hot Conditions, high speeds (Gases)

For high speeds, high pressure and high temperature, specially designed sealing systems are required.

For these applications contact between the moving parts cannot be tolerated, otherwise rapid wear will occur. Fires have been caused by such failures in aero-engines resulting in the total loss of the engine for example.

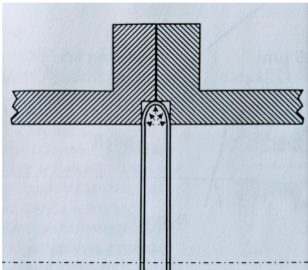

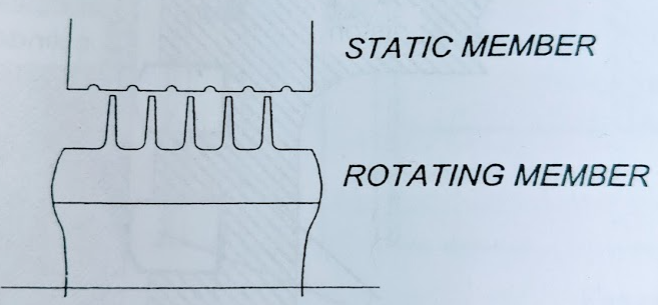

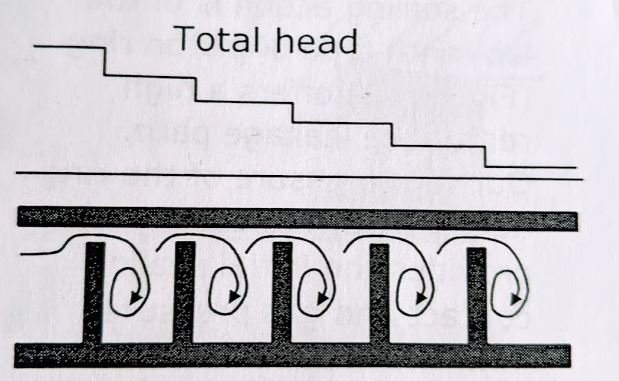

In these cases, labyrinth seals are used. These consist of a series of thin rings running close to, but not touching an enclosed cylinder.

As the gas flows through the slot it gains velocity, resulting in a drop in pressure

The velocity head is lost when the fluid expands into the next inter-ring space. Thus, the pressure is gradually reduced. This process is repeated but with reducing velocity as the fluid passes through each ring, it gradually loses head at each passing section. Note; these seals cannot provide a positive (total) seal, there will always be some leakage

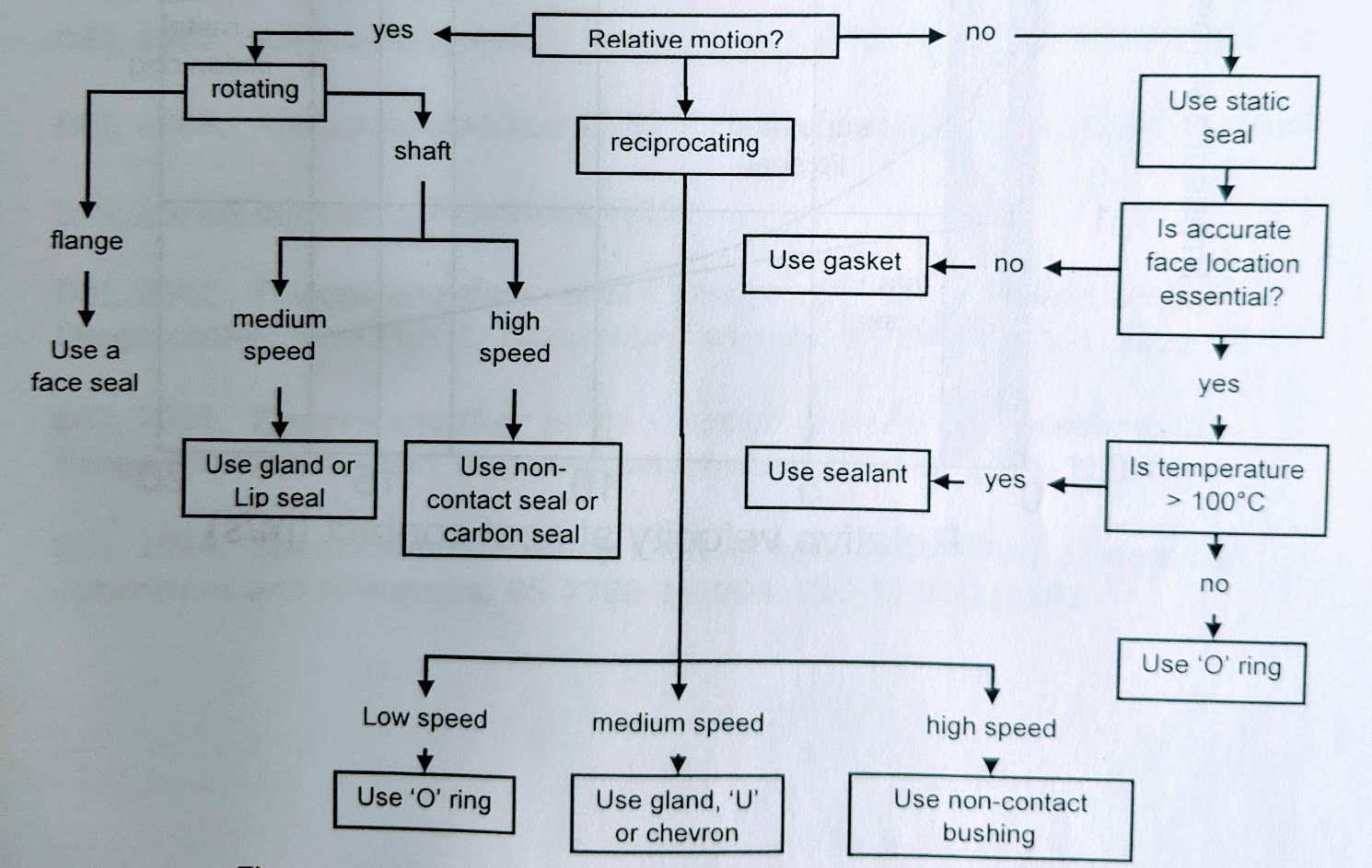

Seal Selection

The below flow diagram can be used as a handy guide when choosing the type of seal to use in your design:

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]