Intelligent Motion: Exploring Manipulation, Mobility, and Control in Robotics

Introduction

The field of robotics has made remarkable strides in recent years, integrating advanced programming methods that enable machines to perform complex tasks across various domains. Among the most significant developments are the manipulation robotic systems, mobile robotic systems, and data acquisition and control robotic systems. Each of these categories addresses unique challenges and applications, from industrial automation and logistics to environmental monitoring and disaster response.

Manipulation robotic systems focus on the precision handling of objects, utilising sophisticated algorithms for kinematics and control to automate assembly processes and enhance productivity in manufacturing. Mobile robotic systems, on the other hand, are designed for navigation and exploration, employing advanced techniques like simultaneous localization and mapping (SLAM) to traverse complex environments autonomously. Finally, data acquisition and control robotic systems serve a critical role in collecting and analysing environmental data, often in real-time, which is essential for informed decision-making in various industries.

Manipulation Robotic System

This system focuses on robots that interact with physical objects.

Programming for manipulation involves:

- Kinematics and Dynamics: Understanding the movement and forces acting on robotic arms.

- Control Algorithms: Implementing PID controllers, inverse kinematics, and path planning algorithms to achieve precise movements.

- Sensors and Feedback: Using sensors like cameras or force sensors to provide feedback for accurate manipulation.

Degrees of Freedom (DOF): typically they have six degrees of freedom, allowing for complex movements and positioning. This configuration enables it to reach and manipulate objects in three-dimensional space effectively.

Payload Capacity: The robot can handle payloads ranging from 150 kg to 300 kg, depending on the specific model. This capacity makes it suitable for heavy-duty applications, such as automotive assembly.

Reach: With a reach of up to 2.6 metres, it can cover a significant workspace, allowing it to operate on large assemblies and in confined spaces.

Precision and Speed: The robot is designed for high-speed operations with a repeatability of ±0.05 mm, ensuring consistent and accurate performance in tasks such as welding or painting.

Advanced Control Systems: features sophisticated control algorithms that enable smooth motion and precise manipulation. It can be programmed for various tasks, utilising software like ABB RobotStudio for simulation and offline programming.

Applications Welding in automotive manufacturing, where precision and speed are critical. In manufacturing environments, it can automate the handling of heavy parts, loading and unloading materials from machines, or transporting components along assembly lines. The robot can perform assembly tasks by accurately positioning components and applying the necessary force, reducing the need for manual labour. It can pick, place, and stack products for shipment. Its precision and ability to reach difficult angles make it suitable for painting applications, ensuring uniform coverage and reducing overspray.

Compliance in Robotic Arms and Hands

In recent years, developers have introduced the concept of “compliance” in robotic arms and hands to address two significant challenges: cost and system safety.

By incorporating compliant materials and structural designs, engineers can enhance the functionality of robotic manipulators while mitigating risks associated with their operation.

Challenges Addressed by Compliance: Increasing the active degrees of freedom in a robotic arm often results in a higher part count, which can drive up system costs and reduce overall reliability. By using compliant materials, manufacturers can simplify designs without sacrificing performance. Powerful actuators can unintentionally cause injury if they apply too much force, whether from a grip that is too strong or an arm that inadvertently pins someone against an object. Incorporating compliance into robotic systems helps to prevent these dangerous scenarios.

Mechanisms for Compliance: Back-Driven Actuators allowing the fingers or grippers to be back-driven enables responsive adjustments based on human interaction, reducing the risk of injury. Compliant Joints can incorporate force and pressure sensors that provide feedback on the amount of force being exerted. This data is crucial for controlling grips on delicate objects and ensuring safe actuation levels Each joint can be equipped with encoders for precise positioning, while vision systems interfacing with the manipulator’s controller can help adjust the manipulator’s orientation to interact better with objects.

Current Applications While compliance offers numerous advantages, many manipulators in industry and academic research are still mounted on non-mobile platforms. Robotic arms with specialised end effectors are prevalent in manufacturing environments, often fixed to assembly line mounts. These stationary systems represent one of the few operational autonomous applications of manipulation. Most mobile applications, such as those involving robots in dynamic environments, are currently teleoperated.

The integration of compliance in robotic arms and hands represents a significant advancement in robotic design, addressing critical issues related to cost, reliability, and safety. As technology continues to evolve, these compliant systems hold the potential to enhance the versatility and efficiency of robotic manipulators, paving the way for broader applications in both industrial and mobile contexts.

Mobile Robotic System

Mobile robots are designed to navigate through environments.

Programming methods include:

Navigation Algorithms: Utilising algorithms like A*, Dijkstra’s, or Rapidly-exploring Random Trees (RRT) for pathfinding.

SLAM (Simultaneous Localization and Mapping) For robots to build a map of an unknown environment while keeping track of their location.

Sensor Integration: Employing LIDAR, cameras, and ultrasonic sensors for obstacle detection and environment mapping.

Example

The Boston Dynamics Spot is a prominent example of a mobile robotic system designed for versatile applications in various environments, including industrial, commercial, and even research settings.

Spot features four articulated legs, enabling it to traverse diverse environments, including stairs, rough terrain, and narrow spaces. Spot can autonomously navigate and map its surroundings using SLAM (Simultaneous Localization and Mapping) technology. This allows it to avoid obstacles and adapt to changing environments. Spot can carry payloads of up to 14 kg (30 lbs) on its back, making it suitable for transporting equipment or tools. The robot’s modular design allows for various attachments, such as robotic arms, cameras, or sensors, enabling it to perform different tasks based on specific needs. Spot can be controlled remotely via a tablet or computer, allowing operators to guide it through complex tasks while maintaining a safe distance, particularly in hazardous environments.

Applications

Industrial Inspection: Spot is used in manufacturing and industrial settings to inspect equipment and infrastructure.

Construction Site Monitoring: The robot can monitor construction sites, providing real-time feedback and data collection to improve safety and productivity.

Public Safety and Security: patrol areas for security purposes, equipped with cameras and thermal sensors to identify potential threats or monitor environments.

Research and Development: In academic and research institutions, Spot serves as a platform for robotics research, allowing experiments in locomotion, navigation, and human-robot interaction.

Healthcare Support: delivering supplies or monitoring patients in hospital settings, enhancing operational efficiency.

One notable application of mobile manipulation is in explosive ordnance disposal, where robots must navigate complex environments and interact with potentially dangerous objects. In this context, the ability to safely and effectively manipulate items while ensuring operator safety is paramount.

Control Input and Output in Mobile Robotic Systems

Control input and output are crucial for the effective operation of mobile robotic systems, enabling them to perceive their environment, make decisions, and execute actions. Understanding these components is essential for designing robots that can operate autonomously and efficiently.

Control Input: Control inputs refer to the data that the robot collects from its environment and the commands it receives to guide its actions.

This input can come from various sources, including:

Light Detection and Ranging sensors create detailed 3D maps of the environment by measuring distances to surrounding objects, aiding in navigation and obstacle avoidance. Visual data from cameras can be processed using computer vision techniques for object recognition, navigation, and interaction with the environment. Ultrasonic and Infrared Sensors measure distances to obstacles, helping the robot avoid collisions and navigate tight spaces

Environmental Feedback: Robots may also receive inputs based on their interactions with the environment, such as tactile sensors on grippers that provide feedback on grip strength and object handling. While many mobile robots operate autonomously, they can also accept inputs from an operator via a control interface. This could include route adjustments, task commands, or operational parameters. Input from GPS or other localization technologies helps the robot understand its position within a larger environment, particularly in outdoor settings

Control Output: Control outputs refer to the actions and responses generated by the robot based on the processed input data. These drive the robot’s movements and behaviours, they can include: Motors and actuators receive commands to control movement, steering, and speed. The robot’s software interprets sensor inputs to generate path-planning outputs, determining how the robot should move through its environment to reach a destination or complete a task. Based on environmental feedback, the robot may adjust its actions, such as slowing down when approaching an obstacle or changing its path when detecting a change in terrain. Mobile robots may communicate their status or findings back to a central system or operator. This could include data logs, alerts about obstacles, or updates on task completion.

Control Systems The interplay between control inputs and outputs is managed through various control systems, which can be categorised as: Feedback Control Systems that use sensor data to continuously adjust outputs. For example, a robot may adjust its speed based on the proximity of obstacles detected by ultrasonic sensors. Feedforward Control systems that anticipate changes in the environment based on known parameters and adjust outputs accordingly. For example, if a robot detects it’s on a slope, it may adjust its motor output to maintain speed. Hybrid Control systems combine feedback and feedforward methods for more sophisticated control. This is particularly useful in dynamic environments where conditions can change rapidly. Advanced mobile robots may use machine learning algorithms to improve their performance over time, learning from past experiences to enhance navigation and decision-making.

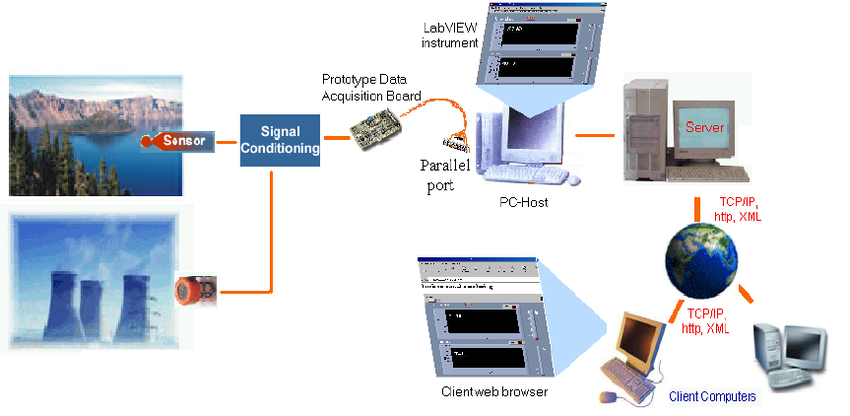

Data Acquisition and Control Robotic System

This system focuses on collecting data from various sources and controlling processes.

Key programming aspects include:

Data Processing: Implementing software to analyse and visualise data from sensors.

Real-Time Control Systems: Developing algorithms for real-time monitoring and control of robotic systems, often using tools like MATLAB or LabVIEW.

Communication Protocols; a set of formal rules describing how to transmit or exchange data between devices.

Example: Environmental Monitoring and Control Robotic System

The system is designed to monitor environmental parameters in a greenhouse and control the climate to ensure optimal plant growth. It collects data such as temperature, humidity, soil moisture, and light intensity. Based on the data, the system adjusts irrigation, lighting, and ventilation automatically

Sensors: Temperature, Humidity , Soil Moisture and Light Sensor (Photometer)

Microcontroller/Processor: A Raspberry Pi or Arduino can be used as the central processing unit that interfaces with the sensors and controls the actuators.

Actuators: Water Pump to control the irrigation system based on soil moisture data. Ventilation Fan to regulate the air circulation depending on temperature and humidity.

Artificial Lighting: Adjusts the light intensity based on the photometer readings.

Data Acquisition System (DAQ):The DAQ system gathers real-time data from the sensors via analog or digital inputs.The processor receives the data and processes it using pre-programmed algorithms.

Control System:The microcontroller triggers the appropriate actuators based on sensor readings. For example, if the soil moisture is low, the water pump will activate to irrigate the plants. If the temperature is too high, the fan turns on for cooling.

Communication System: Wireless Modules (e.g. Wi-Fi, Zigbee, or LoRa) to transmit data to a remote server for monitoring and data storage. Remote Access via a smartphone or computer to allow users to check system status and override controls if necessary.

User Interface (UI): A graphical user interface (GUI) can be developed using web technologies or mobile apps, allowing the user to view real-time sensor data, historical trends, and control actuators remotely.

In an automated control system, sensors play a crucial role by continuously gathering environmental data, such as temperature or soil moisture, and sending it to a microcontroller for processing. Based on this data, the system uses a control loop to make decisions, such as turning on a fan when the temperature exceeds a certain limit or activating an irrigation system when soil moisture is too low.

In addition to real-time control, the system includes data logging and monitoring, where the collected information is stored on a cloud platform or local server. This allows users to monitor trends, like daily temperature changes or soil moisture fluctuations, through a web dashboard or mobile app. Such insights help users optimise the system for better performance.

The system also features a manual override option, enabling users to take direct control over actuators remotely. This added flexibility allows for manual adjustments, offering more control when needed, even when the system’s automated functions don’t immediately trigger the necessary actions.

Benefits: Automation systems have transformed the way we manage environmental conditions by minimising the need for human intervention. These systems automatically adjust settings based on real-time data, creating a more efficient and hands-off approach. By continuously monitoring conditions, they ensure precise resource management, making sure that elements like water, energy, or temperature are optimised without waste. One of the most valuable features is remote monitoring, which allows users to control and monitor the system from anywhere using a connected device. Whether at home or on the go, users can check real-time data and make adjustments as needed, ensuring smooth operation without being physically present. This combination of automation, precision, and remote access enhances both efficiency and convenience in managing critical systems.

Other applications: In smart homes, climate control systems automate heating, cooling, and ventilation, creating a comfortable living environment while optimising energy use. These systems adjust based on real-time data, such as indoor temperature or weather forecasts, and can be controlled remotely through smart devices. In industrial systems, environmental controls in factories maintain optimal conditions for manufacturing processes. These automated systems regulate air quality, temperature, and humidity, improving efficiency and ensuring product quality. The precision and consistency of these controls are vital in maintaining safe and efficient working conditions.

Control loop

Closed-loop control systems are commonly used in robotics. Behaviour-based robotics, a paradigm where robots react to stimuli based on modular behaviours, often uses this structure for real-time responses.

Apply Control Signals: In this step, the robot’s control system generates and sends control signals to its actuators (e.g., motors, wheels, or robotic arms). These signals might command the robot to move forward, turn, or adjust its speed based on its current situation or desired goal. For example, if the robot needs to reach a specific target point, the control signals might direct the wheels to move at a certain speed toward the target.

Measure the Results: The robot constantly collects data from its sensors to measure various aspects of its state, such as:

- Position and orientation (through GPS or odometry)

- Distance to obstacles (through proximity sensors or LIDAR)

- Speed and direction (through encoders and accelerometers)

This sensor data allows the robot to understand its current state in the environment, such as how far it has moved from its original position, how close it is to the target, or whether it is avoiding obstacles.

Generate New Control Signals: The control system compares the robot’s current state to the desired state, or the target it wants to reach. The difference between the current state and the desired state is called the error. For instance:

- If the robot’s goal is to move to a specific point, it will calculate the difference (error) between its current position and the target position.

- If the robot’s goal is to maintain a certain speed, it will compare the current speed to the desired speed and calculate the error.

Once the error is calculated, the control system generates new control signals designed to minimise the error, thus driving the robot closer to its goal.

This step typically involves control algorithms like:

- PID Controllers (Proportional-Integral-Derivative), which calculate the best possible control signals based on the error over time.

- State Estimation: Kalman filters used to filter out the key data are used to smooth sensor data and improve the robot’s internal model of the world.

Repeating the Loop: This loop of applying control signals, measuring results, and generating new control signals continues, allowing the robot to gradually refine its movements and actions. The faster this loop can run (higher frequency), the more responsive and accurate the robot’s control will be, improving performance, particularly in dynamic environments.

Behaviour-Based Robotics Context

In behaviour-based robotics, the robot’s actions are governed by simple modular behaviours, each responding to specific sensor inputs. Each behaviour might be a control loop, with behaviours layered or competing for control.

For example: Obstacle avoidance might dominate if the robot detects an obstacle.

Goal seeking behaviour might dominate when no obstacles are in the path. These behaviours, combined with control loops, allow robots to adapt dynamically to their environment, rather than strictly following a pre-defined sequence of actions. This makes behaviour-based robotics effective for real-time, dynamic environments where a robot needs to react to changing situations continuously.

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]