How to Determine the Appropriate Surface Treatment

Finishing operations are frequently required following the creation of the original part shape by some other processes since the initial processes cannot produce sufficiently high dimensional precision and/or high-quality surface finishes on their own.

The primary industries for application of surface treatments are: packaging, building and construction, and automotive and transportation.

Additional commercial application areas include the following two:

1. in microelectronics, particularly with the development of telecommunications and the widespread use of microprocessor controllers in household items. These need for readily available parts with strong conductivity and the ability to transport extremely small electrical currents. This is accomplished by plating precious metals on less expensive substrates.

2. In printing, where lithographic plates are typically mounted on aluminium substrates. Prior to photosensitive treatments, the aluminium is first subjected to electrochemical graining and anodic oxidation (anodizing).

In order to fulfil functional and aesthetic functions, advanced surface treatments are increasingly being used in the daily production of parts for the automotive sector. The requirements for contemporary machining applications include higher specific loads (mechanical, thermal, etc.), reduced weight and friction, longer component lifetimes, and increased corrosion resistance.

The finishes offered for some selected materials are listed in the table below:

Industries that use surface treatments

Metal and plastic surface treatment does not constitute a separate vertical industry sector in and of itself. Surface modifications do not produce products; rather, they alter the surface characteristics of already-formed components or goods for later use. Printed circuit boards are made through a large number of interconnected production phases and may theoretically be called goods, but they are actually built as components for use in other products. As a result, numerous sectors benefit greatly from the surface treatment of metals and plastics. Some notable clients are listed below:

Automobiles, food and beverage containers, aircraft, printing, information systems, home appliances, telecommunications, jewellery, eyewear, and decorations, heavy engineering, furniture, buildings, apparel, bathroom fixtures, coinage, hardware, and medical are just a few examples.

Key surface treatments and applications

Passivation of chromium and zinc plating applied to steel is a post-treatment process used to improve the corrosion resistance of steel components coated with chromium or zinc. For chromium plating, it enhances the protective oxide layer on the surface. For zinc plating, passivation (often with chromate coatings) forms a thin film that further protects the zinc and underlying steel. This process is widely used in industries like automotive and construction to extend component lifespan and maintain appearance.

Strong chromium plating applied to Steel: Strong (hard) chromium plating is a thick, durable coating applied to steel to enhance wear resistance, surface hardness, and moderate corrosion protection. Commonly used in industrial parts like hydraulic rods and engine components, it reduces friction and extends component life, making it ideal for high-performance applications.

Plating for chromium applied to Steel coil, often referred to as electrolytic chromium coating (ECCS) or tin-free steel, is primarily used in the packaging and appliance industries. The coating provides a thin, corrosion-resistant layer of chromium that enhances the coil’s durability, surface finish, and resistance to rust, while also improving adhesion for paints, lacquers, or adhesives. Though much thinner than hard chrome plating, this layer helps protect steel during forming and fabrication processes. Chromium-plated coils are commonly used in food cans, bottle caps, and household appliance panels, offering a clean, bright appearance and stable surface for further processing.

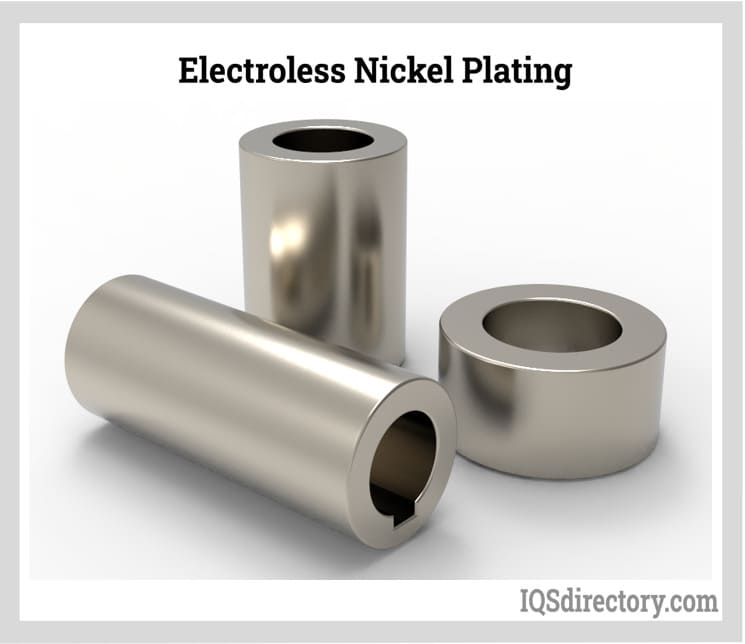

Nickel Autocatalytic Plating for Use with Subsequent Chromium Plating is also known as electroless nickel plating, is widely used as a base layer before applying chromium plating on substrates such as steel, aluminium, and plastics. This process does not require electricity; instead, it relies on a chemical reaction to deposit a uniform nickel-phosphorus (or nickel-boron) coating. The nickel layer provides: Excellent adhesion for subsequent chromium plating, Improved corrosion resistance, Enhanced hardness and wear resistance, A smooth, uniform surface across complex geometries and non-conductive materials like plasticIt is especially valuable when plating parts with intricate shapes or when a conductive layer is needed on non-metallic surfaces. This makes it essential in industries like automotive, aerospace, electronics, and consumer goods.

Electrolytic nickel plating is a process used to coat steel with a thin layer of nickel. This is done by placing the steel in a special liquid (called a plating bath) and using electricity to help the nickel stick to the surface. The nickel coating protects the steel from rust and wear, making it last longer. It also gives the steel a shiny, smooth finish, which makes it look better and feel smoother. This type of plating is often used on car parts, tools, and household items. In many cases, nickel plating is used as a base layer before adding another coating, like chromium, because it helps the next layer stick better and improves the overall quality of the surface.

Copper and brass plating are widely used surface treatments that offer both functional and decorative benefits. Copper plating provides excellent electrical conductivity, making it ideal for electronic components, while also serving as a smooth, adhesive base layer for other finishes like nickel or chromium. Brass plating, which is an alloy of copper and zinc, is often used to give a warm, gold-like appearance to items such as fixtures, hardware, and decorative fittings. Both types of plating help improve corrosion resistance and enhance the visual appeal of steel or other base materials. They are commonly used in industries such as electronics, plumbing, furniture, and interior design, where both appearance and performance are important.

Cadmium plating is a specialized surface treatment primarily used for its excellent corrosion resistance, especially in harsh environments such as marine, aerospace, and military applications. When applied to metals like steel, cadmium forms a protective barrier that resists salt water, chemicals, and atmospheric conditions, making it ideal for parts exposed to the elements. In addition to its protective qualities, cadmium offers good lubricity, allowing moving parts to operate smoothly, and it provides a solderable surface, which is useful in electrical applications. Despite these advantages, cadmium is toxic, and its use is strictly controlled due to environmental and health concerns. Safer alternatives are often considered where possible, but cadmium remains in use for critical applications where its unique properties are essential.

Gold plating is a high-quality surface treatment valued for its excellent conductivity, resistance to corrosion, and distinctive appearance. It involves applying a thin layer of gold onto a base material, typically metals like copper, nickel, or silver, using an electroplating process. Though the gold layer is usually very thin, it provides significant benefits. In electronics, gold plating is widely used on connectors, circuit boards, and contact points because it ensures reliable electrical connections and resists tarnishing over time. In addition to its functional role, gold plating is also popular for decorative purposes in jewellery, watches, and luxury items, offering a rich and attractive finish. While gold is an expensive material, its unique combination of durability, conductivity, and aesthetic appeal makes it ideal for both technical and ornamental applications where quality and reliability are essential.

Plating with precious metals such as platinum, iridium, silver, and others is used in specialized applications where performance, durability, and reliability are critical. These metals are often chosen for their exceptional resistance to corrosion, high electrical conductivity, and ability to withstand extreme conditions. Platinum and iridium are commonly used in high-temperature and chemically aggressive environments, such as in aerospace, medical implants, and catalytic components, due to their stability and wear resistance. Silver plating is valued for its excellent conductivity and is frequently used in electrical and electronic components like switches, connectors, and circuit boards. It also adds a bright, decorative finish for cutlery, musical instruments, and ornaments. Though these metals are costly, their unique properties make them ideal for critical, high-performance, or luxury applications, where standard coatings would not meet the necessary standards for durability, conductivity, or appearance.

Anodising is an electrochemical process used to improve the surface properties of metals, most commonly aluminium. During anodising, the metal is submerged in an acid electrolyte solution and an electric current is applied. This process thickens the naturally occurring oxide layer on the surface, creating a finish that is harder, more durable, and highly resistant to corrosion and wear. One of the key benefits of anodising is that it allows the surface to absorb dyes, making it possible to add decorative colour while still maintaining the metal’s natural texture. Unlike paint or plating, anodising does not peel or chip because the protective layer is fully integrated with the metal surface. Anodised aluminium is widely used in architecture, consumer electronics, kitchenware, automotive parts, and more, where both aesthetic appeal and long-lasting protection are important. It’s a lightweight, environmentally friendly way to enhance the performance and appearance of metal components.

Strong anodising, or hard anodising, is an advanced form of anodising that creates a thick, hard, and highly durable oxide layer on metals—mainly aluminium. It offers excellent wear resistance, corrosion protection, and electrical insulation, making it ideal for demanding applications like aerospace, automotive, and industrial machinery. The coating is tightly bonded to the metal, usually dark in colour, and designed to withstand harsh environments and heavy use.

Conversion coatings are chemical surface treatments used to enhance the corrosion resistance, paint adhesion, and durability of metal components. Unlike traditional coatings that sit on the surface, conversion coatings chemically react with the metal to form a protective layer that becomes part of the material itself. Phosphating is one of the most common methods, typically applied to steel surfaces. It creates a thin, crystalline phosphate layer that provides excellent protection against corrosion and acts as a good base for painting or powder coating. Chromating, often used on aluminium and zinc surfaces, forms a protective chromate film that offers corrosion resistance while maintaining electrical conductivity, making it especially useful in aerospace and electronics. Other conversion coatings, such as anodic films or oxalate coatings, serve similar purposes depending on the base metal and application. These treatments are valued for their ability to extend component life, improve coating adhesion, and reduce maintenance in industries such as automotive, construction, and defence.

Printed circuit boards (PCBs) are essential components in nearly all electronic devices, serving as the platform for connecting and supporting electronic components. The manufacturing process involves several key steps, including etching and plating with metals such as copper and tin. The process begins with a copper-clad board, where a protective mask is applied to define the desired circuit pattern. Etching removes unwanted copper, leaving behind only the circuit traces needed for electrical connections. This precise patterning is critical for the board’s functionality.

After etching, the board undergoes copper plating, which reinforces the circuit paths and often adds copper to drilled holes to form conductive pathways between layers. A final layer of tin plating is applied to protect the copper from oxidation and to provide a solderable surface for attaching components. These steps ensure that the PCB is electrically reliable, durable, and ready for high-performance use in electronics ranging from smartphones and computers to industrial and aerospace systems.

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]