Behind the Cutter: How Milling Shapes the Future of Manufacturing

Secondary processes are used in manufacturing to further modify the output of primary manufacturing processes in order to improve the material properties, surface quality, surface integrity, appearance and dimensional tolerance.

In this blog, we will focus on milling as a secondary manufacturing process.

Machining refers to the mechanical work done by a tool to remove material from the workpiece. As such, machining as a subtractive manufacturing process.

It can provide very good surface finish and intricate shapes with close tolerance.

Milling

Milling produces 3-dimensional shapes with a rotating multi-edge cutting tool. The cutting tool can be programmed to move against a fixed workpiece in almost any direction. Milling tools remove material by their movement in the machine and from their shape.

.

Milling is done using a cylindrical milling tool mounted in a milling tool holder that is then mounted in the tool spindle on the machine.

End Mills – End mills are the most common milling cutters. End mills are available in a wide variety of lengths, diameters, and types. A square end mill is used for most general milling applications. It produces a sharp edge at the bottom of pockets and slots.

Typical End Mill

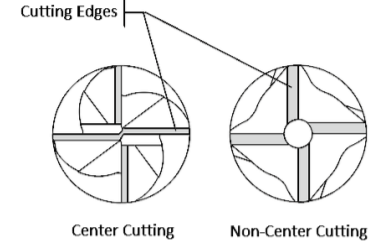

End mills can be center cutting and non-center cutting. As their name implies, center cutting end mills have cutting edges on both the end face of the cutter and the sides. Center cutting end mills are essential for plunge milling.

Non-center cutting end mills have cutting edges only on the sides and are used only for side milling. These tools are identified by a small hole at the center.

Roughing end mills have serrations in the teeth to quickly remove large amounts of material without creating vibration. The serrations produce many small chips and a rough finish.

Roughening end mill

Flutes – Spiral-shaped cutting edges are cut into the side of the end mill to provide a path for chips to escape when an end mill is down in a slot or a pocket. The most common options are 2, 3, or 4 flutes. The more flutes, the more cutting edges but the narrower the channel for chip evacuation.

An important consideration when choosing the number of flutes is called “chip load”. “Chip load” is a measurement of the thickness of material removed by each cutting edge during a cut. The number of flutes you choose depends on the material you want to cut and the capabilities of your machine.

A material like aluminum produces large chips compared to other materials. For that reason, 4 flute end mills are rarely used with aluminum because the flutes can get jammed with chips and break the cutter.

For harder materials, you want to use more flutes. Having more flutes reduces chip load and improves surface finish.

While the number, direction and type of flutes that a cutting tool has can vary widely, the tools most commonly used have two flutes and are up-cut spirals to move the chips up out of the cut.

- Two Flute: Has the greatest amount of flute space, allowing for more chip carrying capacity in softer materials. Used primarily in slotting and pocketing of non-ferrous materials like aluminum where chip removal is a concern.

- Three Flute: Allows for better part finish in harder materials. The three flutes provide for greater strength and the ability to pocket and slot both ferrous and non-ferrous materials.

- Four Flute/Multiple Flute: Ideal for finish milling. The extra flutes allow for faster feed rates to produce a much finer finish than two or three flute tools. However, the reduced flute space may cause problems with chip removal.

The most common flute numbers for general milling operations are two (better space for chip ejection) and four (better surface finish).

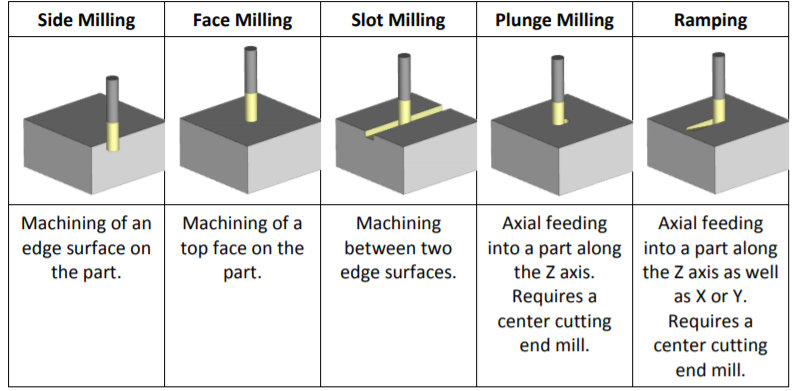

Application of end mills:

Tool Materials –

End mills are made out of either cobalt steel alloys (known as high speed steel, or HSS), or from tungsten carbide in a cobalt lattice (shortened to “carbide”).

- High Speed Steel (HSS): Provides good wear resistance and costs less than cobalt or carbide end mills. HSS is used for general purpose milling of both ferrous and nonferrous materials. While usually inexpensive, HSS does not offer the tool life or speed advantages of cobalt and carbide end mills.

- Cobalt: Cobalt is an M42 tool steel with an 8% cobalt content. Cobalt is more expensive but provides better wear resistance and toughness than HSS (M7). Because the tool can run 10% faster than HSS, metal removal rates and finish are better than HSS.

- Solid Carbide: Carbide is considerably harder, more rigid, and more wear resistant than HSS. However, carbide is brittle and tends to chip instead of wear. Carbide is used primarily in finishing applications. Carbide tools are best suited for shops operating fewer milling machines or machines with minimal spindle wear. Rigidity is critical when using carbide tools. Carbide end mills may require a premium price over the cobalt end mills, but they can also be run at speeds 2 1/2 times faster than HSS end mills.

The choice of tool material depends on the material to be cut as well as on the maximum spindle speed of the machine. Smaller milling machines may not be capable of reaching the spindle speeds recommended for carbide end mills

Face Mills and Indexable End Mills –

Face mills are tools with a large diameter that are used to cut a wide shallow path for facing operations. Facing is used for machining a large flat area, typically the top of the part in preparation for other milling operations.

A face mill is a solid body that holds multiple carbide inserts that can be replaced as they wear out. The more inserts, the faster the metal removal rate.

Cutters with a 45° lead angle are used most frequently.

45° lead angle (top), and 90° (lower) insert cutters shown

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]