The Backbone of Motion: Understanding the Operation and Applications of Bearings

Introduction

Every machine with moving parts, from a bicycle wheel to a jet engine, depends on one simple but vital component: the bearing. Often overlooked due to their small size, bearings are the unsung heroes of mechanical engineering. Their primary role is to support motion, whether rotary or linear, while minimizing friction and handling load. This enables machines to run more smoothly, efficiently, and reliably.

At their core, bearings are precision-engineered elements that allow constrained relative motion between two components. They reduce direct surface contact between moving parts, thereby preventing excessive wear, overheating, and energy loss. Bearings come in various types, ball bearings, roller bearings, plain bearings, and more, each designed to meet specific operational demands.

This blog will guide you through the principles of operation of bearings, explaining how they function under different types of load and movement. We will also explore their typical applications in industries such as automotive, aerospace, manufacturing, and energy. Whether you’re a student, technician, or engineer, understanding how bearings work is crucial to mastering the fundamentals of mechanical systems.

Bearings allow free rotation without any resistance, however they cannot be translated in x and y directions. They often provide support for rotating equipment, e.g. in the internal combustion engine crank shaft.

Radial and axial (thrust) loads:

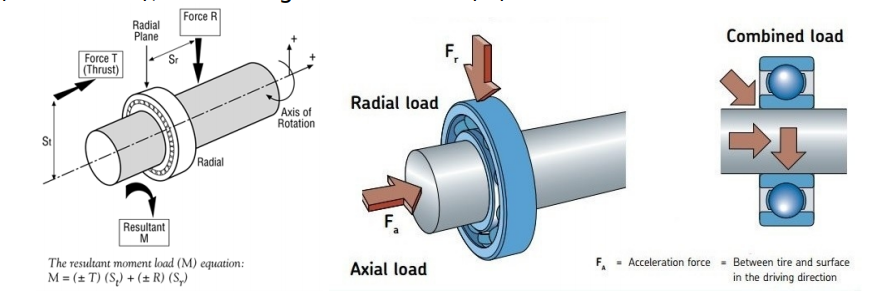

Bearings support a shaft or housing to permit their free motion about an axis of rotation. Load can be applied to bearings in either of two basic directions.

Radial loads act at right angles to the shaft (bearing’s axis of rotation).

Axial (thrust) acts parallel to the axis of rotation.

When these loads are offset from either the bearing axis (distance St) or radial plane (distance Sr), a resulting moment load (M) will be created.

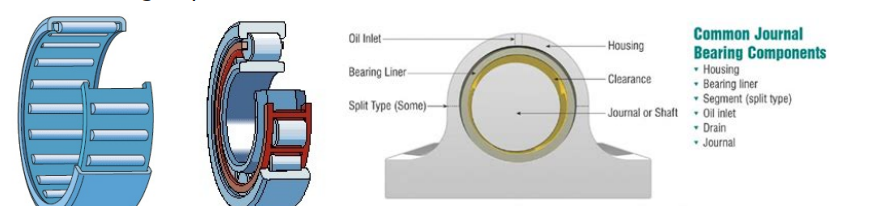

A plain bearing is the simplest type of bearing, composed of just a bearing surface with no rolling elements. Therefore, the journal (the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on. Plain bearings require a constant flow or lubrication.

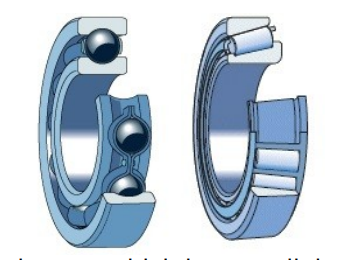

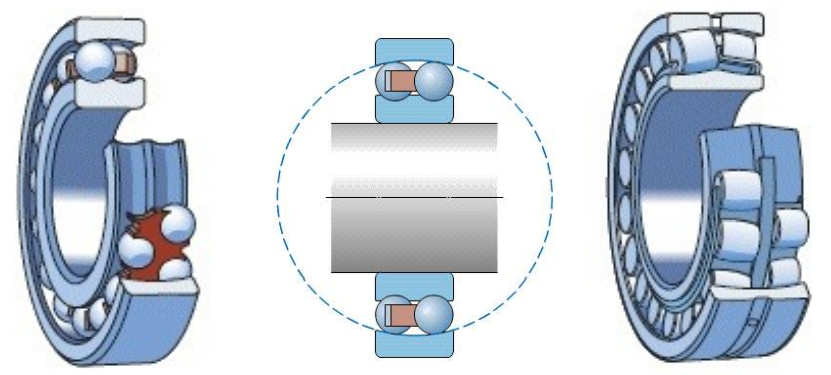

Rolling bearings have a much lower friction and have a series of spherical balls between the two surfaces to allow free rotation. An example of a radial bearing is a journal bearing, a cylindrical roller bearing or a needle roller bearing; most of which can withstand high loads and have high speeds of rotation.

There are certain bearings that are combined radial and axial bearings, such as deep groove ball bearings, that are useful for axial loads and can function at high speeds.

Taper bearings have an excellent load capacity, but function at a low speed and are expensive.

Self aligning bearings exist too, which have a slightly spherical outer surface and can only cope with small axial loads, but have a high radial load capacity and high speeds. Spherical roller bearings are also available which work in the same manor, with the difference being the shape of the rollers (barrelled as oppose to spheres).

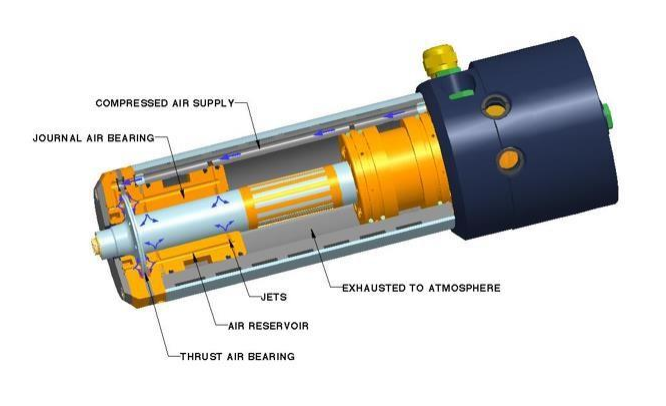

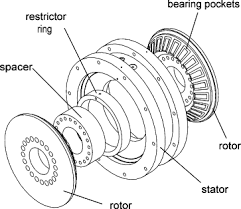

There are three main types of non-contact bearings, two of which rely on an external pressure source such as air or water. There is no friction in aerostatic bearings.

Very little friction is hydrostatic bearings too. These types produce very accurate motion and can withstand very high speeds.

The third type is a magnetic bearing that supports load using magnetic levitation, so there is no mechanical contact with the supported component. There is no speed limit to the rotation, as the only heat generated is by the shearing of the air between the coils and the component.

Interested in our engineering courses?

We have over 70 courses across all major engineering disciplines, including, mechanical, electrical and electronic, civil, aerospace, industrial, computer and general engineering. Visit our course catalogue for a complete list of fully accredited engineering programmes.

A small selection of short courses …

Level 6 Courses

International Graduate Diploma in Mechanical Engineering

Level 5 Courses

Higher International Diploma in Industrial Engineering

Higher International Diploma in Mechanical Engineering

Level 4 Courses

Higher International Certificate in Industrial Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]